Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Product

+86-576-84255555

PRODUCT DESCRIPTION

About us

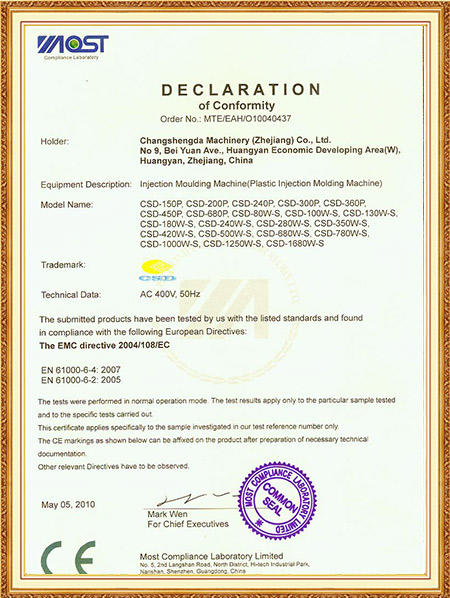

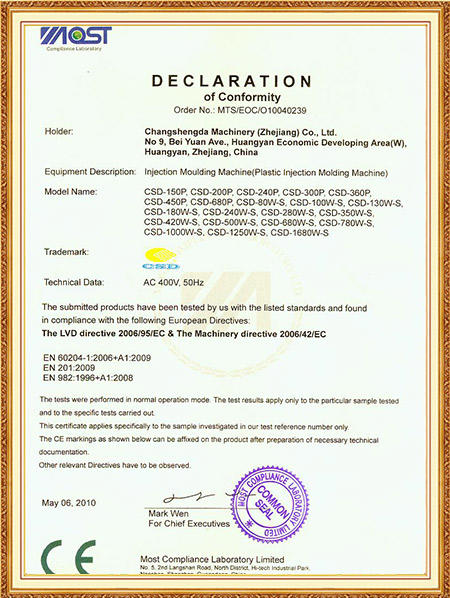

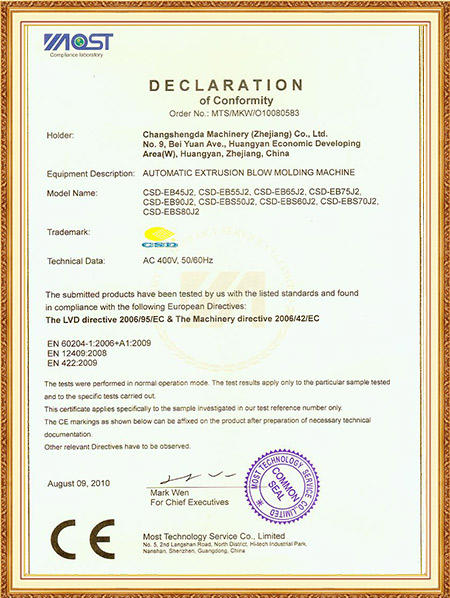

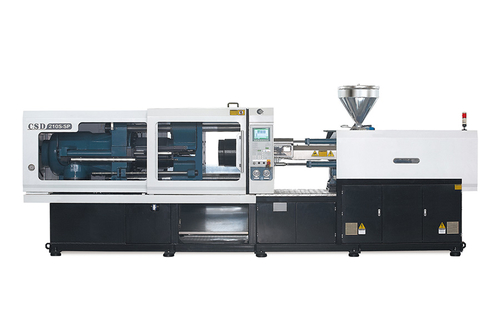

As a famous OEM 2 Cavity Semi-Automatic Blowing Mold Factory and 2 Cavity Semi-Automatic Blowing Mold company, Changshengda Machinery (Zhejiang) Co., Ltd. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million. The plant covers an area of 72,000 square meters. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. High efficiency and favored by domestic and foreign merchants.

The company adheres to the business ethics of "based on honesty, technology as the core, and quality for survival". Adopting advanced design concepts, scientific high-end configuration, advanced processing equipment, and precision manufacturing of Changshengda series products, it can fully meet the different needs of high-end customers at home and abroad.create a high-quality brand and cast a first-class image, we continue to innovate 2 Cavity Semi-Automatic Blowing Mold and implement the service promise of "turnkey project".

We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. Products and thorough after-sales service.

News

-

1. Factors affecting the selection of injection molding machines: The important factors that usually affect the choice of injection molding machine include product weight repeatabi...

-

As a result of injection blow molding, injection molding and blow molding are combined. It is possible to use either a vertical or a horizontal plastifier to convey the thermoplast...

-

The choice of mould steel is of great importance if the blow mold is to function effectively.When plastic is molded, due to molecular stretching and shearing, residual stress is le...

-

Blow moulding machine is a manufacturing process used for the production of plastic bottles, containers, and custom shapes. This manufacturing process can be accomplished through d...

-

When the blow molding machine is working, the liquid plastic is sprayed out, and then the wind force blown by the machine is used to blow the plastic body to a certain shape of the...

-

The processing of blow mold products and toys requires the guarantee of resources to ensure smooth production. Two basic conditions complicate the management of resources. When mul...

Related Products

Your Contact Details

If you are interested in our 2 Cavity Semi-Automatic Blowing Mold or have any questions, please consult us.

Contact us

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语