Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

1. Factors affecting the selection of injection molding machines:

The important factors that usually affect the choice of injection molding machine include product weight repeatability, mold opening position, cycle time, etc. Therefore, the following information must be collected or available before making a selection:

1. Product: size (length, width, height, wall thickness), net weight and total weight, etc.

2. Material: the ratio of raw materials or granulated materials to other materials and crushed materials.

Second, how to choose the model of the injection molding machine

After obtaining the above information, you can follow the steps below to select a suitable injection molding machine:

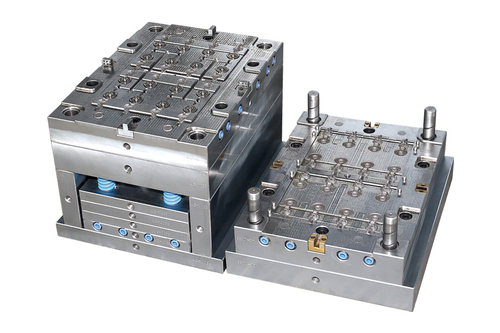

The model and series are determined by the product and plastic. When a customer chooses an injection molding machine, the first step is to determine the structure of the injection molding machine: vertical injection molding machine, angle injection molding machine, or horizontal injection molding machine according to the product removal direction and mold structure. There is little difference in the structure of the glue injection machines of the major manufacturers, and the structure difference is mainly in the clamping structure.

3. Selection of clamping force of injection molding machine:

The mold clamping is determined by the design structure of the product mold and the plastic to determine the "clamping force" tonnage. The clamping force is an important parameter of the injection molding machine. When the high-pressure plastic melt fills the cavity, a large expansion force is generated in the cavity, which causes the mold to expand along the parting surface. If mold expansion is not allowed, the injection molding machine must provide a force greater than this expansion force to lock the mold, otherwise it will cause overflow and runout. This force is the clamping force.

If the clamping force is too large, it will not only increase the customer’s purchase cost, but also increase the wear of the mold and the difficulty of venting in the cavity, causing the product to burn or lack of material. More importantly, the machine will cause the machine to be stressed. Increased wear and tear shortens the life of the clamping mechanism and hydraulic system, and also causes waste of energy. Therefore, when calculating the clamping force, the customer’s product projection area and the ratio of the process length to the wall thickness, material, and mold cavity must be used to calculate the clamping force. The pressure is used to calculate the more accurate clamping force. The clamping force is the same as the injection volume, which reflects the ability of the machine to process the product to a certain extent, and is often used as the main parameter to indicate the size of the machine.

If the clamping force is too large, it will not only increase the customer’s purchase cost, but also increase the wear of the mold and the difficulty of venting in the cavity, causing the product to burn or lack of material. More importantly, the machine will cause the machine to be stressed. Increased wear and tear shortens the life of the clamping mechanism and hydraulic system, and also causes waste of energy. Therefore, when calculating the clamping force, the customer’s product projection area and the ratio of the process length to the wall thickness, material, and mold cavity must be used to calculate the clamping force. The pressure is used to calculate the more accurate clamping force. The clamping force is the same as the injection volume, which reflects the ability of the machine to process the product to a certain extent, and is often used as the main parameter to indicate the size of the machine.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français