Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Product

+86-576-84255555

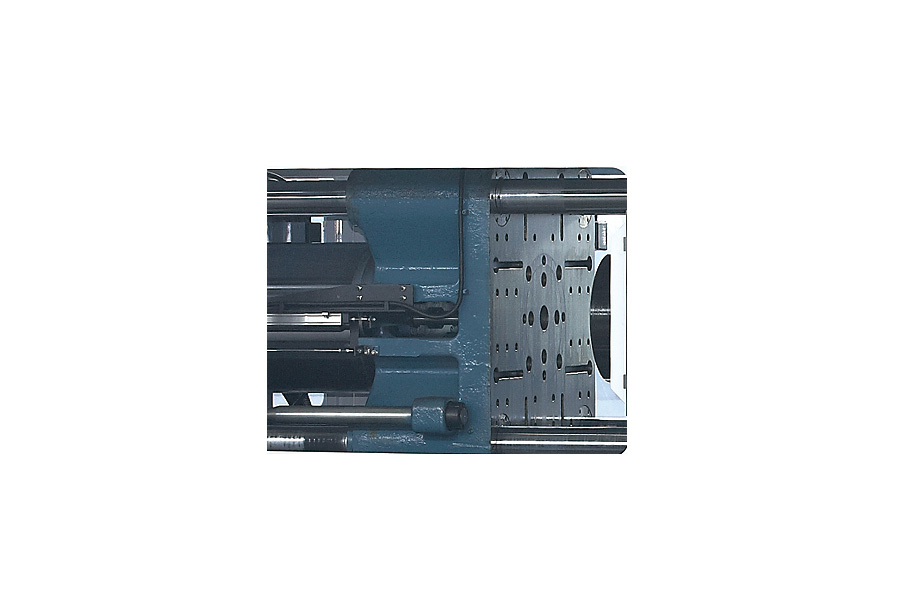

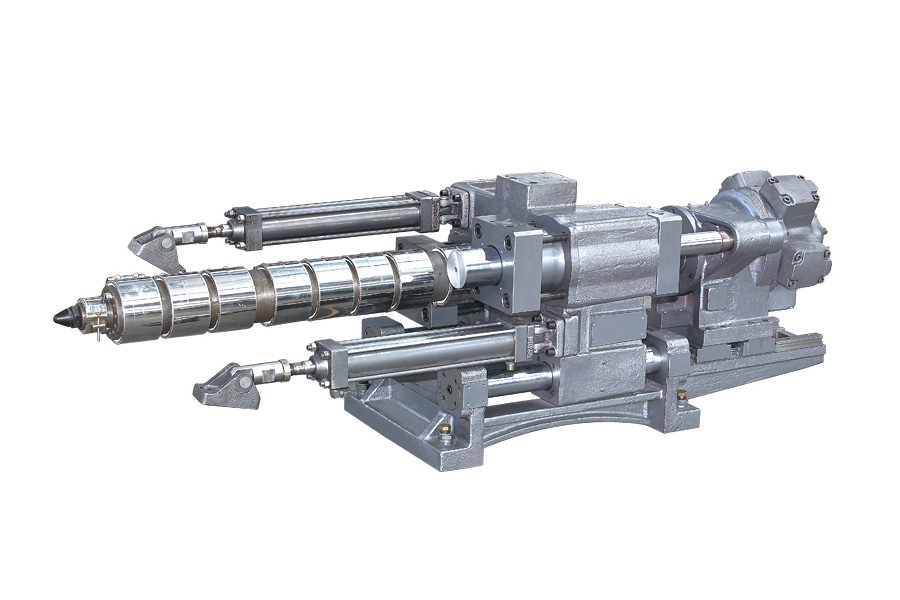

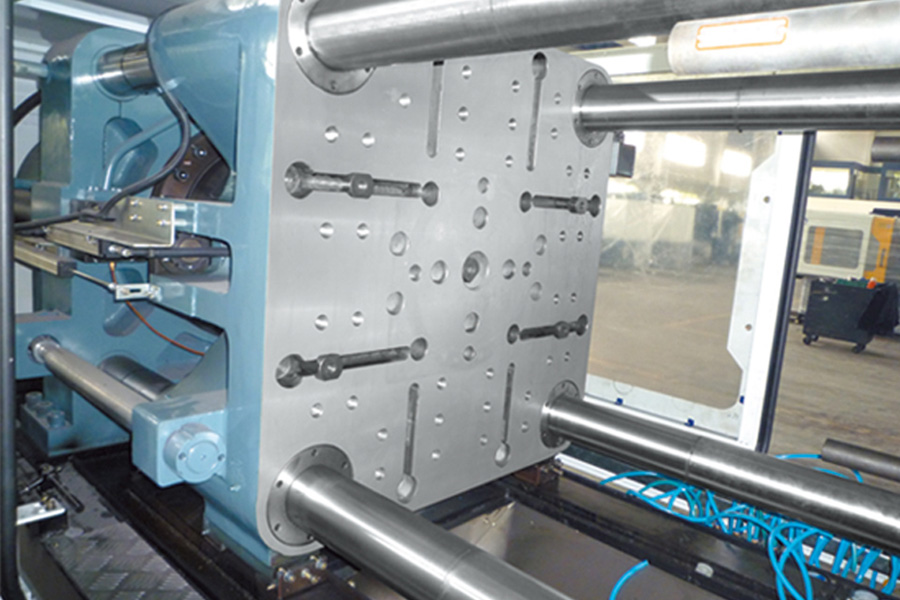

CSD-SP Direct Pressure Injection Molding Machine

PRODUCT DESCRIPTION

| CSD-50-SP | CSD-90-SP | CSD-130-SP | CSD-170-SP | CSD-210-SP | CSD-250-SP | CSD-300-SP | ||||||||||

| A | B | A | B | A | B | A | B | A | B | A | B | A | B | |||

| INJECTION UNIT | Screw Diameter | mm | 30 | 32 | 35 | 37 | 37 | 40 | 40 | 46 | 50 | 55 | 56 | 62 | 60 | 65 |

| Screw L/d Ratio | L/D | 21 | 19.7 | 20.8 | 19.7 | 22.2 | 20 | 22.3 | 20 | 22 | 20 | 22 | 20 | 22 | 20 | |

| Shot Volume(theoretical) | cm³ | 92 | 103 | 150 | 168 | 206 | 241 | 283 | 374 | 471 | 570 | 662 | 812 | 882 | 1035 | |

| Shot Weight | g | 84 | 94 | 137 | 153 | 188 | 219 | 258 | 340 | 429 | 518 | 602 | 738 | 802 | 942 | |

| zo | 2.9 | 3.3 | 4.8 | 5.4 | 6.6 | 7.8 | 9.1 | 12 | 16.4 | 20.1 | 21.2 | 26 | 28 | 33.2 | ||

| Injection Pressure | Mpa | 200 | 175 | 193 | 173 | 220 | 190 | 243 | 184 | 200 | 167 | 196 | 160 | 219 | 187 | |

| Injection Rate | g/s | 53 | 60 | 88 | 100 | 117 | 130 | 124 | 157 | 210 | 254 | 281 | 335 | 272 | 319 | |

| Screw Speed | rpm | 0~220 | 0~220 | 0~200 | 0~200 | 0~200 | 0~200 | 0~200 | ||||||||

| Plasticizing Capacity | g/s | 8.2 | 9.2 | 12.1 | 13 | 12.9 | 15 | 13.6 | 18.6 | 24.1 | 30.8 | 31.3 | 37.4 | 35.7 | 40 | |

| CLAMPING UNIT | Mold Clamp Mode | hydraulic mold clamp | hydraulic mold clamp | hydraulic mold clamp | hydraulic mold clamp | hydraulic mold clamp | hydraulic mold clamp | hydraulic mold clamp | ||||||||

| Clamping Force | KN | 500 | 900 | 1300 | 1700 | 2100 | 2500 | 3000 | ||||||||

| Open Stroke | mm | 420 | 480 | 510 | 660 | 720 | 770 | 820 | ||||||||

| Maiximum Open Distance | mm | 570 | 660 | 710 | 880 | 980 | 1050 | 1250 | ||||||||

| Minimum Mold Thickness | mm | 150 | 180 | 200 | 220 | 260 | 280 | 430 | ||||||||

| Space Between Tie Bars(wxh) | mm | 330x330 | 380x380 | 430x430 | 480x480 | 540x540 | 600x600 | 690x690 | ||||||||

| Ejector Force | KN | 25 | 35 | 45 | 50 | 60 | 70 | 100 | ||||||||

| Ejector Stroke | mm | 80 | 100 | 130 | 180 | 200 | 200 | 230 | ||||||||

| Ejector Number | n | 1 | 5 | 5 | 5 | 5 | 9 | 13 | ||||||||

| OTHERS | Heater Power | KW | 7.2 | 8.5 | 9.3 | 11.6 | 18 | 26 | 35 | |||||||

| A | 32.4 | 38.2 | 41.8 | 52.2 | 81 | 117 | 157.5 | |||||||||

| Pump Motor Power | KW | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | ||||||||

| A | 15 | 22 | 300 | 37 | 44 | 60 | 64 | |||||||||

| Max Pump Pressure | Mpa | 16 | 16 | 16 | 16 | 16 | 16 | 16 | ||||||||

| Hopper Capacity | cm³ | 20 | 25 | 25 | 25 | 50 | 50 | 70 | ||||||||

| Oil Tank Capacity | cm³ | 300 | 350 | 400 | 500 | 600 | 700 | 900 | ||||||||

| Machine Weight | t | 3.0 | 3.8 | 4.5 | 6 | 7.2 | 9.2 | 11.3 | ||||||||

| Machine Dimension(I Xw Xh) | mxmxm | 3.7x1.1x1.5 | 4.2x1.2x1.7 | 4.62x1.3x1.7 | 5.42x1.48x1.72 | 6.0x1.47x1.83 | 6.42x1.68x2.0 | 7.0x2.0x2.3 | ||||||||

| DIMENSIONS | Platen Dimensions(front) | mm |  |

|

|

|

|

|

|

|||||||

| Platen Dimensions(side) | mm |  |

|

|

|

|

|

|

||||||||

| Machine Dimension | mm |  |

|

|

|

|

|

|

||||||||

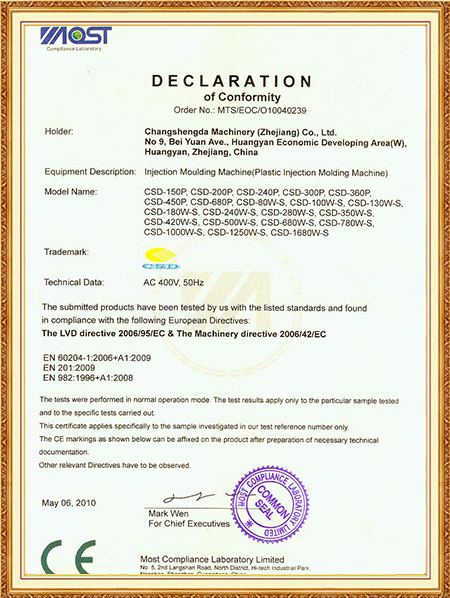

About us

As a famous Custom CSD-SP Direct Pressure Injection Molding Machine Suppliers and CSD-SP Direct Pressure Injection Molding Machine company, Changshengda Machinery (Zhejiang) Co., Ltd. was established in 1992, a wholly-owned Australian enterprise with a registered capital of US$5.2 million. The plant covers an area of 72,000 square meters. Now it has successfully cooperated with dozens of domestic well-known brand enterprises. High efficiency and favored by domestic and foreign merchants.

The company adheres to the business ethics of "based on honesty, technology as the core, and quality for survival". Adopting advanced design concepts, scientific high-end configuration, advanced processing equipment, and precision manufacturing of Changshengda series products, it can fully meet the different needs of high-end customers at home and abroad.create a high-quality brand and cast a first-class image, we continue to innovate CSD-SP Direct Pressure Injection Molding Machine and implement the service promise of "turnkey project".

We have set up many after-sales service agencies at home and abroad to provide new and old customers with high cost performance. Products and thorough after-sales service.

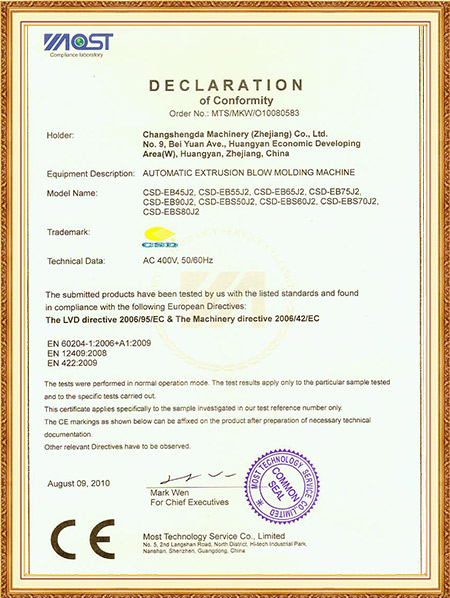

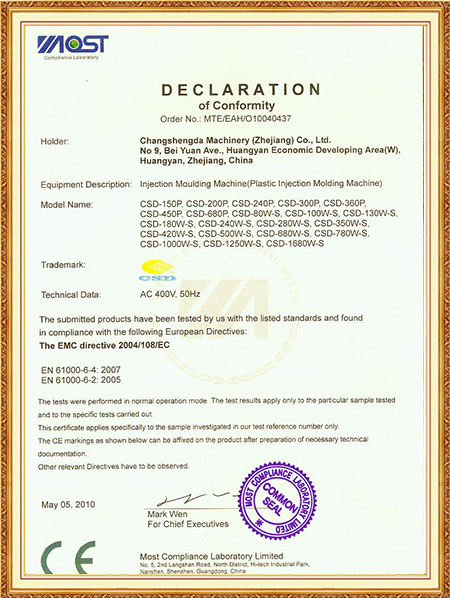

Our Honour&Qualification

News

Related Products

Your Contact Details

If you are interested in our CSD-SP Direct Pressure Injection Molding Machine or have any questions, please consult us.

Contact us

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français