Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

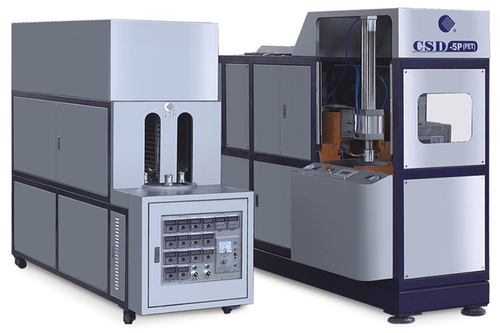

1. The cost of blow moulding machine(especially blow molding molds) is lower (when molding similar products, the cost of blow molding machines is about 1/3-1/2 of that of injection molding machines), and the consumption cost of products is also lower.

2. Plastic molding consumes blow molded products with complex and irregular shapes.

3. The molecular weight of blow molding grade plastics (such as PE) is much higher than that of injection molding grade plastics. As a result, blow molded articles have high impact toughness and high resistance to environmental stress cracking and are suitable for consumer packaging or containers or drums for transporting detergents and chemicals.

4. Blow molding can consume blow molding products with smaller wall thickness.

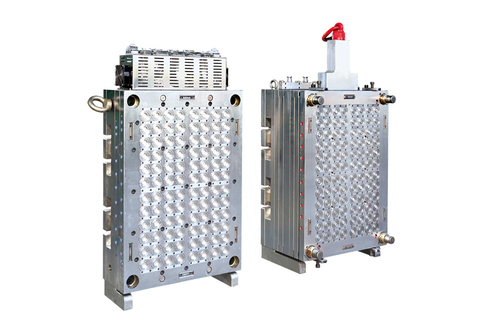

5. Since the blow mold is only composed of concave molds, the wall thickness of the product can be changed by complex adjustment of the mold gap or extrusion conditions, which is very beneficial for products that cannot accurately calculate the required wall thickness afterwards.

6. In blow molding, the parison is formed by the high pressure of the die head, and high pressure blow molding (a few are 0.2-1.0MN), so the residual stress of the product is small, and it is resistant to various stresses such as stretching, impact, bending, and the environment.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français