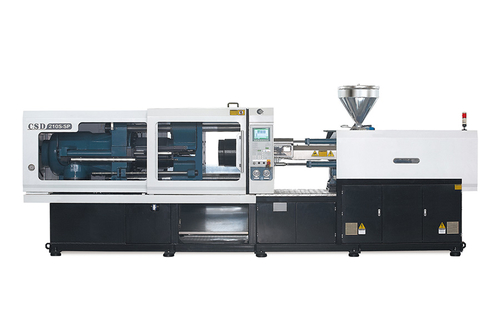

Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The head of the large-scale hollow material low molding machine separates the two functions of the material storage in the storage head of the extruding and blowing hollow material hollow blow molding machine and the injection and extrusion of the parison. The injection plasticizing structure is completed, so that the machine head has the advantage of continuous machine head easy to change color and material. It achieves high parison component repeatability, high plasticizing ability, short color change and material change time, and high strength in the melt fusion seam area.

Extrusion and blowing large hollow material ie plastic) hollow blow molding machines generally use a storage type head, which has a messy internal structure and many parts. Therefore, from the characteristics of the storage type head itself, it is inevitable that there will be a long time for color change and material change, metering Accuracy prohibition and other defects.The large-scale hollow blow molding machine is a comprehensive hollow blow molding machine that combines the injection and plasticizing organization of the injection molding machine with the blow molding and clamping organization of the hollow blow molding machine.

It achieves high parison component repeatability, high plasticizing ability, short color change and material change time, and high strength in the melt fusion seam area. The large-scale hollow plastic hollow blow molding machine generally adopts the storage type head, which has a messy internal structure and many parts. Therefore, from the characteristics of the storage type head itself, it is inevitable that there will be defects such as long color change and material change, and measurement accuracy is prohibited.

The head of blow molding machine the injection blowing large hollow plastic hollow blow molding machine separates the two functions of the material storage in the material storage head of the extrusion blowing hollow plastic hollow blow molding machine and the injection and extrusion of the parison, and is completed by the injection and plasticization organization. In this way, the machine head has the advantage of easy color change and material change of the continuous machine head.

Extrusion and blowing large hollow material ie plastic) hollow blow molding machines generally use a storage type head, which has a messy internal structure and many parts. Therefore, from the characteristics of the storage type head itself, it is inevitable that there will be a long time for color change and material change, metering Accuracy prohibition and other defects.The large-scale hollow blow molding machine is a comprehensive hollow blow molding machine that combines the injection and plasticizing organization of the injection molding machine with the blow molding and clamping organization of the hollow blow molding machine.

It achieves high parison component repeatability, high plasticizing ability, short color change and material change time, and high strength in the melt fusion seam area. The large-scale hollow plastic hollow blow molding machine generally adopts the storage type head, which has a messy internal structure and many parts. Therefore, from the characteristics of the storage type head itself, it is inevitable that there will be defects such as long color change and material change, and measurement accuracy is prohibited.

The head of blow molding machine the injection blowing large hollow plastic hollow blow molding machine separates the two functions of the material storage in the material storage head of the extrusion blowing hollow plastic hollow blow molding machine and the injection and extrusion of the parison, and is completed by the injection and plasticization organization. In this way, the machine head has the advantage of easy color change and material change of the continuous machine head.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français