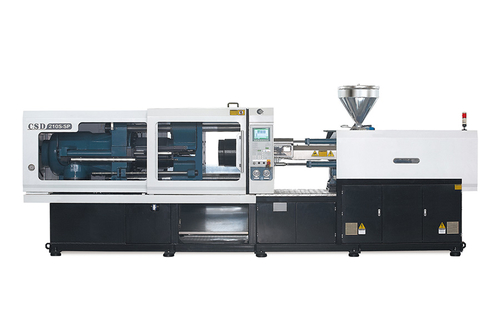

Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Blow molding technology is a rapidly developing plastic processing method. The tubular plastic parison obtained by extrusion or injection molding machine of thermoplastic resin is placed in a split mold while it is hot (or heated to a softened state), and compressed air is introduced into the parison immediately after closing the mold to blow the plastic parison. It expands and sticks closely to the inner wall of the mold, and after cooling and demoulding, various hollow products are obtained.

1. Raw materials for hollow blow molding: polypropylene, polyvinyl chloride, polyethylene, polystyrene, linear polyester, polycarbonate, polyamide, cellulose acetate and polyacetal resin.

2. During the period, the consumption of high-density polyethylene occupies the first place. It is widely used in the packaging of food, chemical industry and processing liquids. High-molecular-weight polyethylene is suitable for the manufacture of large fuel fermented tanks and barrels.

3. Because of its good transparency and air tightness, polyvinyl chloride is widely used in the packaging of cosmetics and detergents. With the development of non-toxic polyvinyl chloride resins and additives, as well as the development of stretch blow molding technology , the use of polyvinyl chloride containers in food packaging has increased rapidly, and has begun to be used in the packaging of beer and other beverages containing carbon dioxide gas.

4. Linear polyester material is a new type of material that has entered the field of hollow blow molding in recent years. Because of its glossy appearance, excellent transparency, high mechanical strength and good preservation of items in the container, waste incineration treatment It has the advantages of not polluting the environment and other aspects, so it has developed rapidly in packaging bottles, especially in the use of pressure-resistant plastic food containers.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français