Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

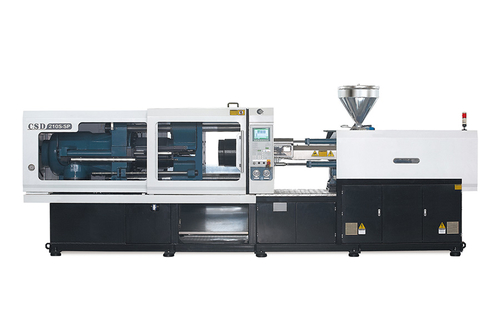

An injection molding machine is a type of manufacturing equipment used to produce a wide range of plastic parts and products. The process involves injecting molten plastic material into a mold cavity, which is then cooled and solidified to form the final product.

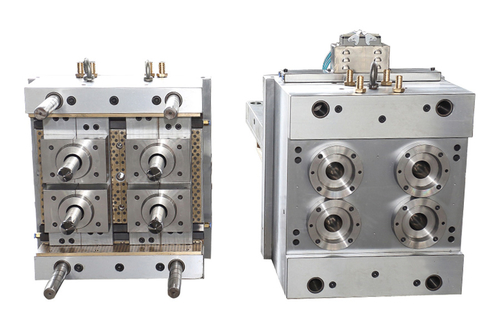

The injection molding machine consists of several key components, including the injection unit, the clamping unit, and the control system. The injection unit includes the hopper, where the plastic material is fed into the machine, and the screw or plunger that melts and injects the plastic into the mold. The clamping unit holds the mold in place and applies pressure to keep it closed during the injection process. The control system manages the various machine settings, such as temperature, pressure, and cycle time.

There are several types of injection molding machines, including hydraulic, electric, and hybrid models. Each type has its own advantages and disadvantages, depending on the specific application and production needs.

Injection molding is widely used in the production of consumer products, automotive parts, medical devices, and many other types of plastic components.

CSD-PET-DP High Speed Preform Production Line

Innovation: synchronization of mold opening, ejection and charging

High speed: Nitrogen assisted injection system

Features: Direct pressure mold clamping system, the most stable mold clamping system

Environmental protection: No contact between 4tie bars andmoving template, lubricating oil free

Precise:Servo valve injection system, 100% accurate in repeated injection

Performance: Double differential circuit, mold clamping speed is increased

Energy-saving: Double closed-loop servo system

Control: European brand is applied in temperature control, temperature control土0.5℃

Advantage:One station manufacturingfor the preform mold and injection molding machine,48 cavity production cycles reaches 12s.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语