Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Advantages of blow molding machine include:

CSD-LP High Speed Automatic Blow Molding Machine

CSD-LP High Speed Automatic Blow Molding Machine

Minimum cost of material and lowestenergy consumption

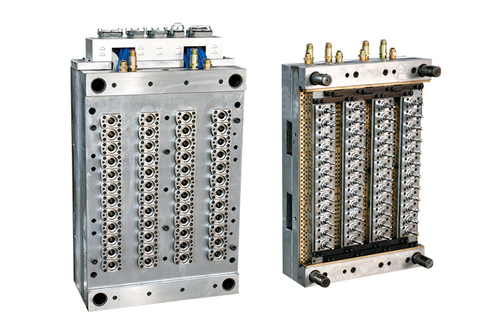

CSD-LP High Speed Automatic Blow Molding Machine is for producing PP plastic bottles. With over 40 years of experience and outstanding performance, it has become one of the most famous production lines in world market. This machine can be used to produce 500ml, 600ml, 1L, 1.5L, 2L PET preforms with 28-30mm neck which match most common bottle sizes for water beverage as well as cosmetic and pharmaceutical industries. It is well known for its reliable quality and high productivity which is used in factories all over the world

Low labor costs: The process is highly automated, requiring minimal human intervention.

High production rates: Blow molding machines can produce large numbers of parts quickly and efficiently.

Versatility: Blow molding can be used to produce a wide range of products, including bottles, containers, and other hollow shapes.

Cost-effective: Blow molding is a cost-effective way to produce large numbers of parts, especially when compared to other plastic molding methods.

Material savings: Blow molding process can make use of a wide range of plastic materials, including HDPE, LDPE, PP, PVC, etc.

Possibility of creating complex shapes: Blow molding can produce complex shapes with high accuracy and consistency.

Can be used for both small and large parts: Blow molding machines are available in a wide range of sizes to accommodate small and large parts.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français