Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Blow molding has become one of the widely used methods for creating plastic containers, and a key component of this process is the blow moulding mould. Over the years, the technology behind blow moulding moulds has significantly advanced, making it possible to produce bottles with greater precision, efficiency, and customizability. As the demand for sustainable packaging solutions grows, manufacturers are focusing on refining blow moulding mould designs to produce eco-friendly bottles while enhancing their durability and functionality.

In 2024, the importance of blow moulding moulds in the production of bottles continues to grow as industries like food and beverage, pharmaceuticals, personal care, and cleaning products rely heavily on these molds to meet the needs of the modern consumer. With the increasing focus on sustainability, the industry is seeing innovations in the materials used for blow molding and a shift toward circular production methods that emphasize recycling and waste reduction.

What is Blow Molding and How Do Molds Work?

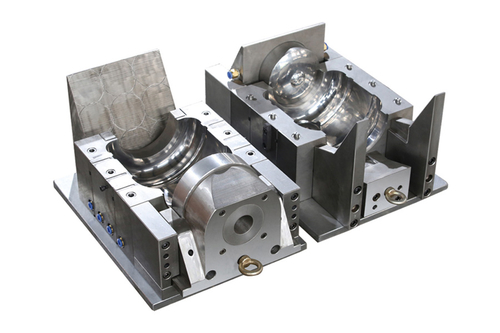

Blow molding is a manufacturing process used to produce hollow plastic parts, commonly bottles. The process starts with a plastic tube, or parison, that is heated and then placed into a mold. The mold is then closed, and air is blown into the parison to inflate it, forcing it to conform to the shape of the blow moulding mould. After cooling, the molded bottle is ejected from the mold, and the process is repeated.

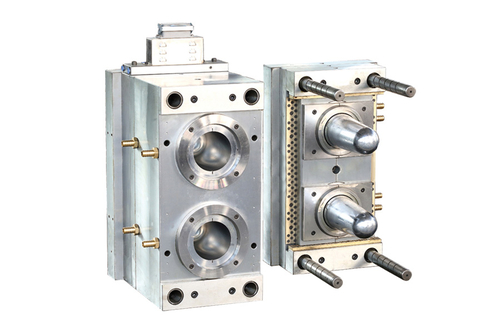

The key to the blow molding process lies in the blow moulding mould, which determines the shape, size, and final characteristics of the bottle. Blow moulding moulds are typically made of steel or aluminum and are carefully designed to withstand the high temperatures and pressures involved in the blow molding process. Advanced designs often feature multiple cavities, allowing for the production of multiple bottles simultaneously, which increases the efficiency of production.

Advancements in Blow Moulding Mould Technology

The blow moulding mould industry has witnessed significant advancements over the past few years, driven by a combination of technological improvements and evolving consumer demands. One of the notable trends is the introduction of multi-cavity molds, which enable the production of several bottles at once, increasing productivity while reducing cycle times. This innovation has been especially beneficial for high-volume industries such as beverage and consumer goods packaging.

In addition, 3D printing technology is starting to play a role in the development of blow moulding moulds. While 3D printing is primarily used for prototyping, it has allowed mold designers to test and refine their ideas quickly and inexpensively. This has sped up the design process, to faster time-to-market for new bottle designs. Furthermore, 3D-printed molds can be used to create complex, intricate designs that would be difficult or impossible to achieve with traditional molding techniques.

Another major innovation in blow moulding mould design is the use of advanced cooling systems. Efficient cooling is essential in the blow molding process to prevent warping and ensure uniform wall thickness in the finished product. Modern blow moulding moulds now incorporate cooling channels that are optimized for faster and more uniform cooling, improving cycle times and reducing the risk of defects. These innovations are making it possible to produce higher-quality bottles with more precise tolerances.

Sustainable Blow Molding: A Focus on Eco-friendly Molds

As sustainability continues to be a major driving force in the packaging industry, blow moulding moulds are also evolving to meet the demand for more environmentally friendly packaging solutions. One of the significant developments in this area is the increased use of recycled materials, such as rPET (recycled polyethylene terephthalate), in the production of blow molded bottles. Manufacturers are now designing blow moulding moulds that can accommodate recycled materials without compromising the strength or quality of the bottles.

In addition, some companies are exploring biodegradable plastics and bio-based resins, which can be used in blow molding. These materials are derived from renewable sources and offer a more sustainable alternative to traditional petroleum-based plastics. As these eco-friendly materials become more common, blow moulding moulds will need to be adapted to handle the unique characteristics of these resins, such as their different melting points and flow behavior.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français