Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

An automatic injection molding machine is a high-speed, efficient, and reliable manufacturing tool that is used in various industries for mass production of plastic products. One of the standout features of this machine is its oil-free lubrication mold clamping system, which enhances its performance and efficiency. This feature allows for a machine that runs fast and smooth, without any oil leakage on the surface, making it a top-performing machine in the market.

The oil-free lubrication mold clamping system is designed to reduce maintenance requirements and increase the lifespan of the machine. With this system, there is no need for oil lubrication, which eliminates the risk of oil leakage while reducing the likelihood of mechanical failure. As a result, the machine requires less maintenance, which saves time, money, and resources.

The oil-free lubrication mold clamping system also ensures a clean and hygienic machine performance. Without the need for oil, there is no greasy film, which reduces the accumulation of dust and dirt on the machine's external surface. This feature ensures that the machine remains clean and hygienic, and also reduces the risk of contamination of the molded parts.

Another key feature of an automatic injection molding machine with an oil-free lubrication mold clamping system is its enhanced durability and efficiency. The system allows for a smooth running machine, which reduces vibrations and noise, preventing wear and tear of machine parts. This, in turn, prolongs the lifespan of the machine, ensuring consistent and reliable performance for years to come.

Furthermore, the oil-free lubrication mold clamping system also contributes to the machine's speed and accuracy. The system ensures that the machine runs smoothly without any friction, thus ensuring that production is completed faster and with greater precision. This feature increases production efficiency and accuracy, allowing for higher output and cost savings.

Lastly, the oil-free lubrication mold clamping system also contributes to a better working environment. The system eliminates the need for oil changes, which reduces contamination and waste disposal, making the working environment greener by reducing the environmental impact. Additionally, it also helps in creating a cleaner and safer working environment, reducing the risk of injury caused by oil leaks and spills on the factory floor.

An automatic injection molding machine with an oil-free lubrication mold clamping system is an advanced and innovative piece of machinery that combines efficiency, accuracy, durability, and a clean and safe working environment. This system eliminates the need for oil lubrication, reduces maintenance requirements, and increases the lifespan of the machine. It also ensures that the machine runs fast and smooth, without oil leakage on the surface, enhancing machine performance and efficiency. As a result, it is an ideal machine for small or large-scale production of plastic products and is increasingly becoming the preferred choice of manufacturers across various industries.

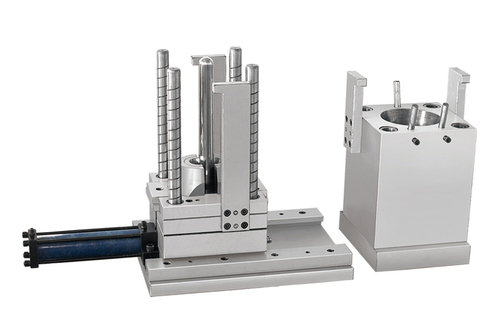

CSD-SP Direct Pressure Injection Molding Machine

CSD-SP Direct Pressure Injection Molding Machine

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语