Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the manufacturing process of plastic bottles, a preform mold plays a crucial role. Here's how a preform mold works:

1.Preform Injection: The process begins with injecting molten plastic material, usually PET (polyethylene terephthalate), into the preform mold. The plastic material is injected under high pressure and at a controlled temperature.

2.Mold Cavity Formation: The preform mold consists of multiple cavities, each shaped like a half-formed bottle. The molten plastic material fills these cavities, taking the shape of the desired bottle's neck and body.

3.Cooling and Solidification: After the molten plastic fills the mold cavities, the cooling process begins. The mold is designed to facilitate the rapid cooling of the plastic material, allowing it to solidify and take the shape of the bottle preform.

4.Ejection: Once the plastic material has solidified, the preform mold opens, and the formed preforms are ejected. The ejection can be done manually or with the assistance of automated mechanisms.

5.Further Processing: The ejected preforms undergo additional processing steps before becoming fully-formed bottles. These steps typically include reheating the preforms to a specific temperature to make them malleable, stretching them using a stretch blow molding process, and then finally inflating them to the desired shape and size using compressed air.

6.Quality Control: Throughout the manufacturing process, quality control measures are implemented to ensure the preforms meet the required standards. This can include visual inspections, dimensional checks, weight measurements, and other quality assurance tests.

By using preform molds, manufacturers can efficiently produce bottle preforms with consistent quality and accuracy. The preform molds allow for high-speed production, precise shaping of the preforms, and effective cooling to ensure dimensional stability. The preforms produced in the preform molds serve as the starting point for the subsequent bottle manufacturing processes, enabling the production of various plastic bottles for different applications.

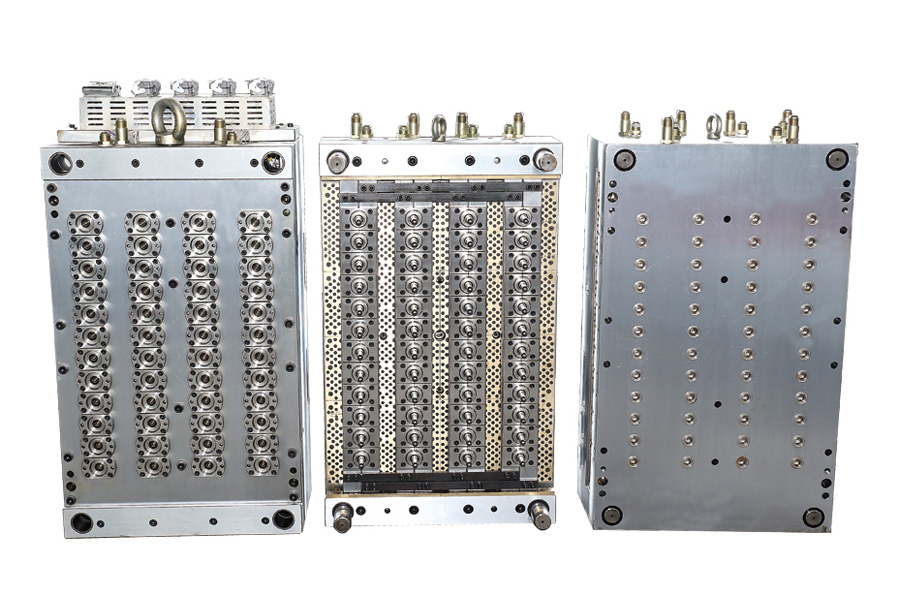

Two Weights Prefrom Hot Runner Sharing Mold

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语