Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The automatic blow molding machine stands as a testament to the evolving landscape of manufacturing, revolutionizing the production of plastic containers and hollow products. This cutting-edge machine seamlessly combines advanced technology with precision engineering, breathing life into everyday objects. In this captivating description, we will embark on a journey to explore the innovative features and transformative capabilities of the automatic blow molding machine, unveiling its impact on various industries and its ability to reshape the manufacturing landscape.

The automatic blow molding machine redefines efficiency in the manufacturing realm. This state-of-the-art equipment employs advanced automation systems, minimizing manual intervention and streamlining the production process. With computer-controlled operations, the machine ensures consistent and accurate results, optimizing cycle times and reducing production costs. From material loading to mold clamping, parison formation, and blow molding, every step is precisely controlled, maximizing productivity. The machine's high-speed capabilities, combined with rapid mold changeovers, enable seamless production runs with minimal downtime. With its ability to produce complex shapes and sizes at impressive speeds, the automatic blow molding machine is a cornerstone of efficient and cost-effective mass production.

At the heart of the automatic blow molding machine lies its ability to deliver unparalleled precision. Advanced sensors monitor key parameters such as temperature, pressure, and parison thickness, ensuring precise control throughout the molding process. This precision engineering results in consistent wall thickness, uniform distribution of material, and superior product quality. The machine's servo-driven movements, synchronized with the parison's inflation, enable precise control over the final shape and dimensions of the blown product. From small containers to large industrial tanks, the automatic blow molding machine produces products with exceptional accuracy, meeting the most stringent industry standards.

The automatic blow molding machine showcases remarkable versatility, catering to a wide range of product requirements. With its modular design, the machine accommodates various mold types and sizes, facilitating the production of diverse shapes and volumes. It supports a wide array of materials, including polyethylene, polypropylene, PET, and more, enabling the creation of products with varying properties, from flexible to rigid. The machine's versatility extends to its ability to incorporate features such as handles, threads, or complex patterns during the blow molding process. This flexibility empowers manufacturers to meet evolving market demands and explore innovative designs. With its versatility and adaptability, the automatic blow molding machine plays a vital role in industries such as packaging, automotive, healthcare, and consumer goods.

The automatic blow molding machine represents a transformative force in manufacturing, redefining the production of plastic containers and hollow products. With its unrivaled efficiency, precision engineering, and versatility, it has become a cornerstone of modern production processes. Embrace the power of innovation and experience the extraordinary capabilities of the automatic blow molding machine as it shapes the future of manufacturing.

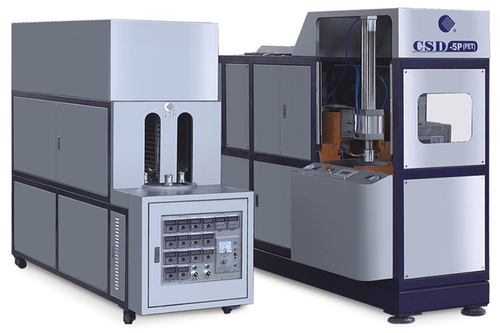

CSD-LP High Speed Automatic Blow Molding Machine

CSD-LP High Speed Automatic Blow Molding Machine

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语