Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Blowing moulding mould technology stands as a cornerstone in modern manufacturing processes, facilitating the production of a wide array of plastic products that range from everyday consumer items to complex industrial components. This innovative method involves shaping molten plastic into hollow forms by inflating it within a mould, enabling the creation of lightweight, durable, and intricately designed products that meet stringent quality standards. As industries continue to evolve, blowing moulding mould technology remains instrumental in driving efficiency, customization, and sustainability across various sectors.

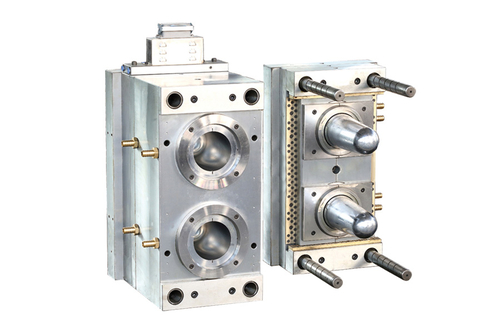

Blowing moulding mould technology is celebrated for its ability to achieve precision and consistency in product manufacturing. The process begins with heating plastic resin to a molten state and injecting it into a specially crafted mould cavity. Once injected, high-pressure air is blown into the mould, forcing the molten plastic to conform to the intricate details of the mould's interior. This technique allows for the production of products with precise dimensions, intricate shapes, and complex geometries that meet exacting specifications.

Industries such as packaging, automotive, healthcare, and consumer goods benefit significantly from blowing moulding mould technology. In the packaging sector, manufacturers utilize this method to produce bottles, containers, and jars of various sizes and shapes. These products are not only lightweight and durable but also offer barrier properties, ensuring the preservation and protection of food, beverages, and pharmaceuticals.

Recent technological advancements have revolutionized blowing moulding mould processes, enhancing production efficiency and reducing cycle times. Automated systems equipped with computer-controlled operations monitor and adjust critical parameters such as temperature, pressure, and cooling rates in real-time. This level of precision minimizes defects and ensures consistent product quality batch after batch.

Moreover, innovations in mould design and materials have further optimized the blowing moulding mould process. Advanced materials such as high-performance alloys and composite resins enhance mould durability, withstand high temperatures, and prolong operational life. These improvements contribute to increased productivity, reduced maintenance downtime, and overall cost-effectiveness for manufacturers.

In response to growing environmental concerns, blowing moulding mould manufacturers are increasingly adopting sustainable practices. Many companies incorporate recycled plastics and bio-based materials into their manufacturing processes, reducing dependence on virgin plastics and lowering carbon footprints. Closed-loop recycling systems are also employed to reclaim and reuse post-consumer and post-industrial plastic waste, promoting a circular economy where materials are continuously recycled and repurposed.

Furthermore, the lightweight nature of products produced using blowing moulding mould technology contributes to energy savings during transportation and distribution. This reduces greenhouse gas emissions and environmental impact throughout the product lifecycle. Manufacturers continue to innovate with eco-friendly materials and processes, aligning with global sustainability goals and consumer demand for greener alternatives.

The global market for blowing moulding mould technology continues to expand, driven by increasing demand across diverse industries and regions. Manufacturers are strategically expanding their operations and investing in research and development to stay competitive in a dynamic marketplace. Collaborations with industry partners, academic institutions, and research organizations facilitate innovation and knowledge exchange, to breakthroughs in materials science, process optimization, and product development.

Emerging markets present new opportunities for blowing moulding mould technology, particularly in regions experiencing rapid industrialization and infrastructure development. Manufacturers are adapting their strategies to meet local market demands, regulatory requirements, and consumer preferences for high-quality, affordable products.

Despite its many advantages, blowing moulding mould technology faces challenges such as fluctuating raw material costs, regulatory compliance, and competitive pressures. Manufacturers must navigate these obstacles while maintaining operational efficiency, product quality, and sustainability initiatives.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français