Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

-

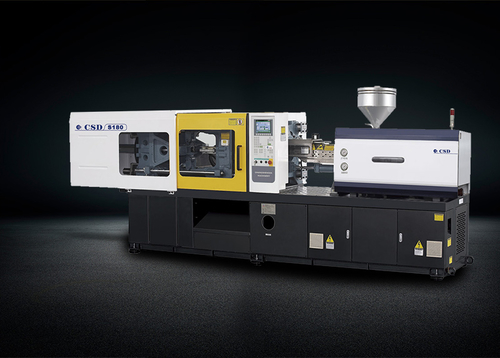

Injection molding machine

Read MoreProfessional PET screw and barrel improve preforms quality and finishedproducts rate.Full closed cover available for internal cooling equipment.

Separate oil circular controlsupports synchronous mould open/close ejection function.Backproducts belt conveyor available forthe preform coolingand the connecting continuousautomatic production line.

An automatic injection molding machine is a type of industrial equipment used for manufacturing plastic parts and products by automatic injection molding machine into a mold. It typically consists of a hopper for holding the raw plastic material, a heating system for melting the material, a screw or ram injector for injecting the melted material into the mold, and a mold clamping mechanism for holding the mold closed during the injection process. The machine is controlled by a computer program, which allows for precise control of the injection process and the ability to produce high-quality, consistent parts.

-

Blow Molding Machine

Read More1. Mechanical motion controlled by hydraulic system and supervised by remote-controlled computer ensure machine steadable running without noise.

2. Equipped with casting aluminum heater, temperature controlled by computer.

3. PLC program controls the machine operation swiftly and accurately.

4. Parison controller equipped on die head guarantees the wall thickness of bottle to be even.

5. Screw rotating speed can be adjusted by inverter in a wide range.

6. Special blowing design minimizes the wasted material.

7. With European Community Safety Attestation TtUV CE certificate.

An automatic blow molding machine is a machine used to produce hollow plastic parts, such as bottles and containers, through a process called blow molding. The machine typically consists of a preform injection system, a blow mold, and a take-out system. The preform injection system injects molten plastic into a mold, which is then blown into the final shape using high-pressure air. The take-out system removes the finished product from the machine. Automatic Blow Molding Machine can produce a wide range of products with high precision and efficiency.

-

Mold

A Food & Beverag Mold, in the context of food and beverage manufacturing, is a type of mold used to create a specific shape or form for a container that will hold food or beverages. These molds are typically made of metal and are used in the blow molding process to produce containers such as bottles and jars. The preform is heated and then blown into the mold to take on the shape of the mold. This process allows for the mass production of containers with consistent size, shape, and quality. Preform molds can be customized for specific products and packaging requirements. The preform mold is an important tool for many food and beverage manufacturers because it allows them to create consistent, high-quality containers for their products.Read More

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语