Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

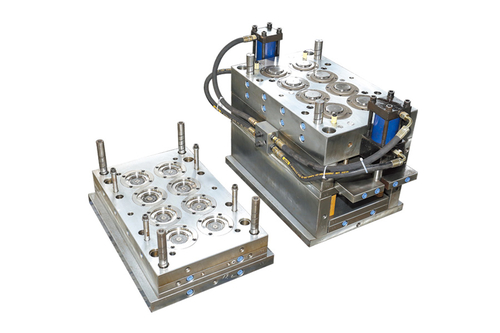

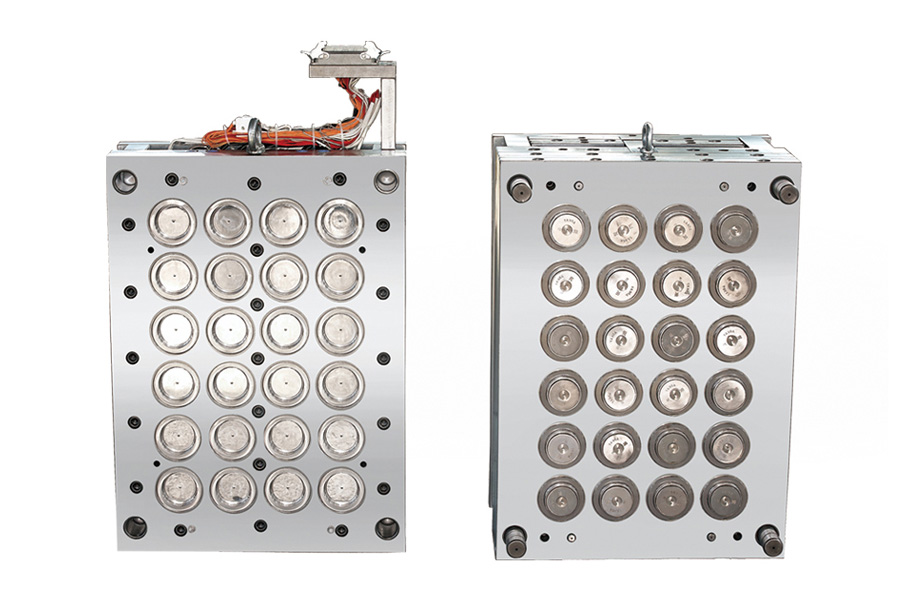

Cap Mold

It is usually composed of a three-part force-plug structure. The inner wall of a cap has bayonet-type lugs which establish twist-lock engagement with the container. There is a first mutual relationship between the parts and a second mutual relationship between the parts during molding operation. The third mutual relationship between the two parts is the axial ejection of the molded part.When injection molding a closed-end piece, the male mold structure can be used. This piece can be a bottle or container closure cap. Its cylindrical body has external flutings. It has an integral internal sealing sleeve that projects a part of the axial distance toward the open end.The materials used to make a cap mould are extremely important for the quality and durability of the end product.

Stainless steel is an excellent choice for cap moulds because of its durability and its ability to produce a number of caps at one time. The exact design of the mould is very important because it needs to withstand thousands of pounds of pressure while being able to eject parts without damaging them.A cap molding mold is generally comprised of three components: an inner ring, a core mold, and an outer head. The inner head contains the body portion of the mold and the top wall surface. The core mold has a copper or aluminum-based thermal conductivity, while the outer peripheral mold surface is made from an iron-based material.To make a cap mold, the first step is to prepare the cap plastic. This plastic should be as thin as possible.

Allow it to dry for an hour before spraying it with silicone. This plastic may feel soft at first, but it is just a thin layer and will become more durable over time. Make sure there are no holes or cracks in the cap plastic before assembling it.If you are looking for a way to shorten the lead time for a custom cap mold, consider integrating Cimatron CAD/CAM software into the design process. This system enables mold makers to take advantage of pre-set, automated design rules that allow for rapid mold delivery. This can reduce the engineering phase of a project from three to four weeks to just a few days. With FastTrack(tm), custom mold makers can compress the manufacturing and engineering phases to less than six weeks.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语