Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The blow molding machine is divided into a two-step blow molding machine and a one-step blow molding machine. The one-step blow molding machine is mainly used for blowing pe and PVC raw plastic bottles, while the two-step blow molding machine is widely used in carbonated beverage bottles, mineral water bottles, cosmetic bottles, edible oil bottles, pesticide bottles, large-caliber bottles, and high-temperature resistant bottles. and other packaging containers of any shape. For companies producing these pet plastic bottles or mineral water companies, what is the difference between a fully automatic blow molding machine and a semi-automatic blow molding machine, and what are the advantages of a fully automatic blow molding machine?

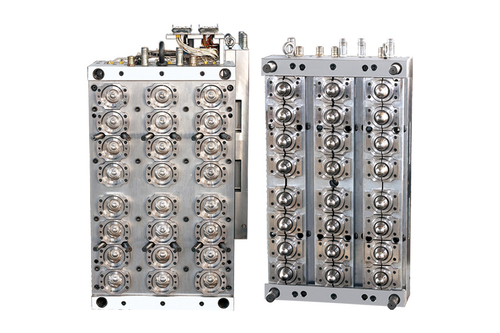

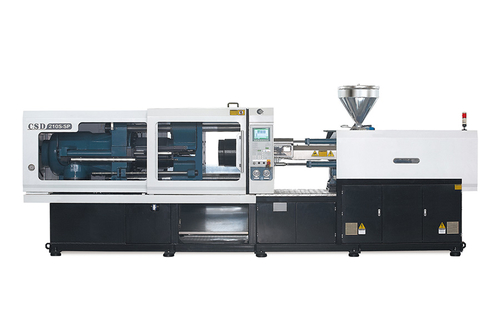

CSD-S-FG Direct Pressure Injection Molding Machine

CSD-S-FG Direct Pressure Injection Molding Machine

Environmental protection : oil free for the equipment surface

High speed: single cylinder injection

Energy saving:servo double closed loop system

Characteristic: straight mode of mold opening and closing

Precision: linear guide used in injection station, for open and close mode

Advantage: large mold opening distance

Control: european famous brand is adopted, temperature control±o.5℃

The difference between automatic blow molding machine and semi-automatic blow molding machine:

1. Different design structures: The fully automatic blow molding machine is all directly and automatically operated by machinery. The fully automatic blow molding machine blows the bottle through the steps of automatic bottling, preform handling, heating, mold clamping, pre-blowing, stretching, and air blowing. The semi-automatic blow molding machine requires manual intervention when loading, running and unloading, which is easy to cause injury to the operator.

2. Different functions and output values: The automatic blow molding machine is generally relatively stable, the equipment works for a long time, and the output can be maintained as if it is turned on. However, the semi-automatic blow molding machine has limited energy for the operator and cannot keep up with the operation process, resulting in less and less output value.

3. The actual sales price is different: the sales price of the fully automatic blow molding machine on the market is slightly higher than that of the semi-automatic blow molding machine. The market price of the semi-automatic bottle blowing machine is within 100,000 yuan, the price of the full-automatic bottle blowing machine is about 120,000-140,000, the price of the one-out four full-automatic bottle blowing machine is about 240,000-250,000, and the price of the full-automatic bottle blowing machine is about 240,000-250,000. The price of the automatic blow molding machine is around 450,000-480,000. For the automatic blow molding machine, the more the number of mold cavities, the more expensive the blow molding machine.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français