Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

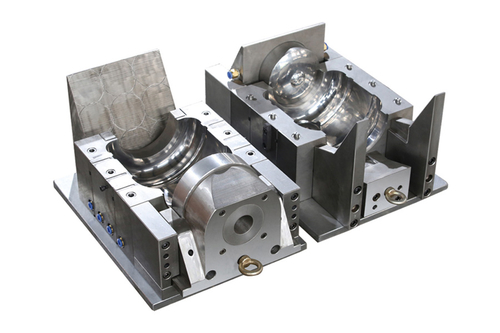

1 Cavity Automatic Blowing Mold

In some machines, compressed air is used to convey the plastic pellets to the extruder hopper, while vacuum conveying is another option.Extrusion blow molding equipment must be cleaned properly after use to reduce contamination. The most common area to experience contamination is on the accumulator head. To minimize the risk of contamination, increase the pinching gap in the accumulator head. In addition, keep the accumulator settings at a safe level to reduce the amount of resin displacement.A Continuous blow molding machine is a machine that uses a continuous extrusion process to create plastic containers. This process involves a rotating screw that turns while the plastic parts move in a continuous stream. As they move through the machine, molds are placed over them, and the cycle continues until the preform is fully formed.

The preform has a neck portion, a collar below it, and a body extending from the neck portion. The body consists of a first cylindrical portion with a first diameter, and a second cylindrical portion that gradually decreases in diameter. The preform is then wrapped around a cylinder to form a finished container.Continuous blow molding machines can be divided into two types: asymmetric and symmetric. Both types of preforms can be oriented asymmetrically. An asymmetric preform includes a handle integrated into the body. The handle is rotated via a preform orientation system, which guides its rotation and linear extension.Injection stretch blow moulding is a manufacturing process which produces plastic products in a variety of shapes and sizes. Compared to injection molding, the process uses less material, and is very flexible.

Its advantages include improved barrier properties, malleability and impact tolerances. In addition, the process can reduce the weight of the product by as much as 10 percent.Injection stretch blow moulding machinery uses a series of molds to produce large volumes of a variety of products. Usually, these machines are used for large runs of a variety of plastic products, including peanut butter jars, liquor bottles, and water bottles. The molded product is then cooled and blown into shape.This process is also used for rapid prototyping. Injection stretch blow moulding machines can produce high-quality plastic containers in a matter of weeks. The main material used is PET. However, other materials can also be used.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français