Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Pet preform specifically refers to a small plastic tube or cylinder that is used as a starting material for the manufacturing of PET (polyethylene terephthalate) bottles and other plastic containers. It is essentially a test tube-like structure that is melted and blown into the desired shape to form a finished product.

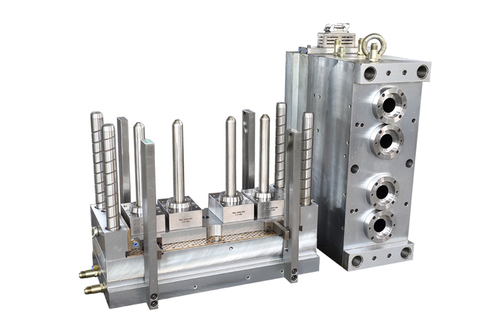

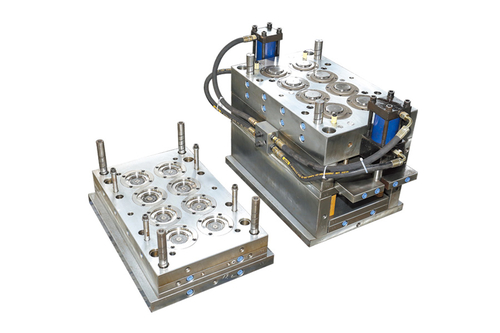

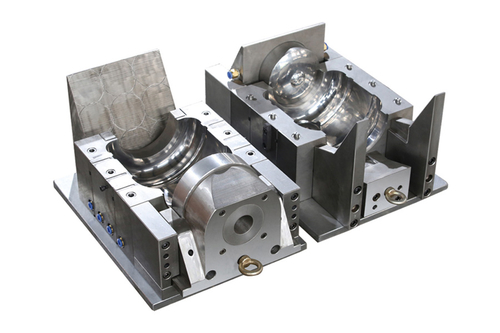

A preform mold is a type of mold used in the production of PET (polyethylene terephthalate) preforms for stretch blow molding. The mold is used in the injection molding process to form the initial preform shape. The preform mold typically consists of two halves that are clamped together and have a cavity in the shape of the preform. Molten plastic material is injected into the cavity to form the preform shape, which is then cooled and ejected from the mold. Preform molds can be made of various materials, including steel and aluminum, and can be designed to produce preforms in different shapes and sizes to meet the specific requirements of different applications.

Pet preforms are typically small, plastic tubes or bottles that are used to make various types of PET (polyethylene terephthalate) containers. Some of the characteristics of PET preforms include their durability, strength, transparency, and ability to withstand high temperatures. They are also lightweight and recyclable, making them a popular choice for many different types of packaging applications. PET preforms can be manufactured in various shapes and sizes, depending on the intended use of the final product.

5 Gallon Preform Mold

5 Gallon Preform Mold

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语