Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

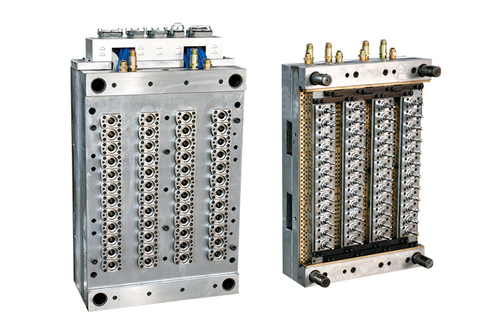

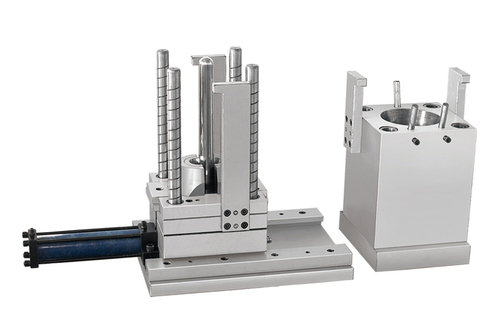

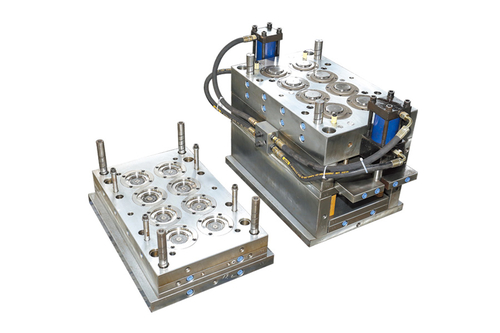

A cap mold is a type of injection mold used for manufacturing plastic caps. Caps are essential components of product packaging and are used in a wide range of industries, including food and beverages, pharmaceuticals, and cosmetics. Cap molds are designed with advanced technology to ensure precision, reliability, and efficiency in the production of high-quality caps. There are several features that set cap molds apart from other molds used in the plastic manufacturing industry.

Firstly, cap molds are highly customizable. Manufacturers can tailor the molds to produce caps in a variety of shapes, sizes, and designs. This level of flexibility allows for customization of products, which is essential for manufacturers looking to differentiate their products from competitors. The customized caps can feature unique shapes or logos, making the final product more appealing to customers.

Another essential feature of cap molds is their durability. These molds are designed with high-quality materials and come with a long life span. The molds can withstand thousands of cycles of use and can still produce high-quality caps with consistent quality. The durability of cap molds makes them a sound investment for manufacturers, as they offer a lower total cost of ownership and a higher return on investment.

Cap molds also offer better accuracy than other molds in the manufacturing industry. The use of advanced technology in the design and construction of the molds ensures that every cap produced is high quality and consistent in dimensions, weight, and appearance. The high accuracy of cap molds reduces material waste and lowers the number of rejects and reworks. This increases the efficiency of the production process and results in lower costs for manufacturers.

Cap molds are also designed with a multi-cavity option, which allows for the production of multiple caps simultaneously. This reduces the time needed to produce large quantities of caps, making the production process more efficient and cost-effective. The multi-cavity option of cap molds also results in higher production rates, which means manufacturers can meet their customers’ demands more quickly.

Additionally, cap molds offer simpler designs than other molds in the industry, which makes them easier to maintain and repair. The simpler design reduces the time and cost required for maintenance and repairs. Cap molds also feature an automated ejection system, which eliminates the need for manual ejection of caps by operators. This results in a safer and more efficient production process.

Another essential feature of cap molds is their ability to produce caps using various materials, such as polypropylene, polyethylene, and PET. The molds are designed to offer flexibility in the production of caps with different physical attributes, such as color, gloss, and texture. This allows manufacturers to cater to the needs of different industries using the same mold, which saves time and increases efficiency in the production process.

Finally, cap molds offer sustainability benefits to manufacturers. The molds produce caps that are lightweight and consume less material, making them eco-friendly. Additionally, caps require less space for storage, which reduces transportation costs and carbon emissions.

Cap molds are essential for manufacturers in the plastic industry. The high customization, durability, accuracy, multi-cavity option, simple design, material flexibility, and sustainability benefits make cap molds a wise investment for manufacturers looking to improve their production processes. The features of cap molds ensure the production of high-quality caps with consistent dimensions, weight, and appearance, which helps manufacturers meet the demands of their customers effectively.

Cap Mold

Cap Mold

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语