Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the process of plastic mold injection molding, temperature control is extremely important, it will not only affect the quality of the product but also affect its molding cycle. Different plastics have different fluidity, so their temperature control is also different. Plastics with good fluidity are generally controlled at about 60°C; plastics with poor fluidity are generally controlled at 80°C to 120°C. In addition, the cooling process of crystalline plastics and non-crystalline plastics is different, which should be noted in the injection molding process.

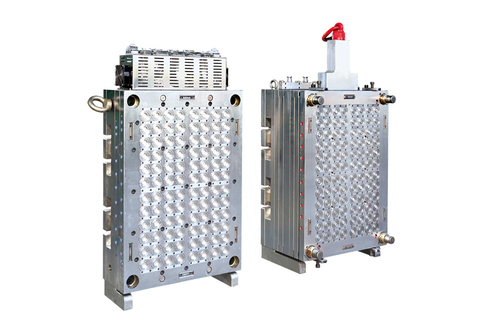

72 Cavity Hot Runner Medical Products Mold

72 Cavity Hot Runner Medical Products Mold

During the injection molding process of plastic molds, if the temperature is too high, it will affect the uneven shrinkage rate of the molding, resulting in deformation of the molded product; if the temperature is too low, it will reduce its fluidity, resulting in defects or flow lines on the surface after molding. If the temperature of the mold is uneven, the temperature after curing will also be uneven, which will cause stress, deform and crack the molded product. Therefore, the temperature control has a great influence on the shrinkage rate, stability and quality of the product. We must pay special attention to plastic mold injection.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语