Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

(1) Injection system Effect of injection system: Injection system is one of the most important components of Ningbo injection molding machine. Generally, there are three main methods: plunger type, screw type, and screw pre-plastic plunger injection type. Now the most widely used is the screw type. The effect is that in a cycle of the injection molding machine, a certain amount of plastic can be heated and plasticized within a specified time, and the molten plastic can be injected into the mold cavity through the screw under a certain pressure and speed. After the injection, the molten material injected into the cavity is fixed. Composition of injection system: The injection system consists of plasticizing equipment and power transmission equipment. The plasticizing equipment of screw injection molding machine is mainly composed of feeding equipment, barrel, screw and nozzle. The power transmission equipment includes injection cylinder, injection seat moving cylinder and screw drive equipment (melting motor).

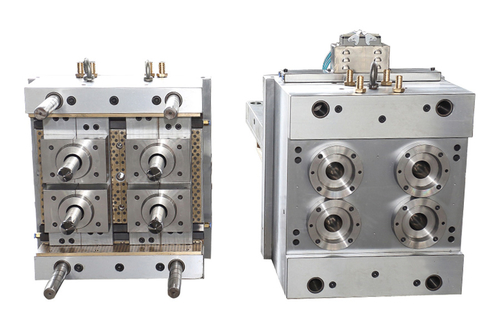

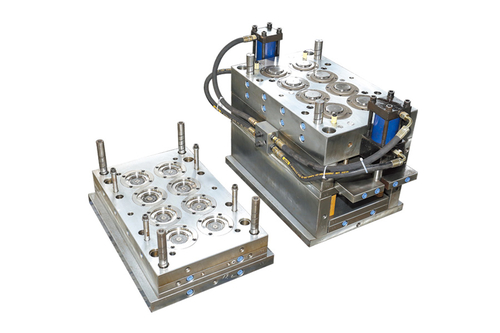

(2) Mold clamping system The effect of the mold clamping system: The effect of the mold clamping system is to ensure that the mold is closed, opened and ejected. At the same time, after the mold is closed, the mold is provided with a satisfactory clamping force to resist the cavity pressure caused by the molten plastic entering the mold cavity, and to avoid the mold from opening seams, resulting in unfavorable status of the product. The composition of the mold clamping system: the mold clamping system is mainly composed of mold clamping equipment, mold adjustment organization, ejection organization, front and rear fixed template, movable template, mold clamping cylinder and safety maintenance organization.

(3) Hydraulic system The effect of the hydraulic transmission system is to complete the injection molding machine to supply power according to the various actions required by the process, and to meet the requirements of the pressure, speed, temperature, etc. required by each part of the injection molding machine. It is mainly composed of various hydraulic components and hydraulic auxiliary components, among which the oil pump and the motor are the power source of the injection molding machine. Various valves control oil pressure and flow, and then satisfy the requirements of injection molding process.

(4) Electrical control system The electrical control system and hydraulic system are reasonably coordinated to complete the process requirements (pressure, temperature, speed, time) and various program actions of the injection machine. It is mainly composed of electrical appliances, electronic components, appearance, heaters, sensors, etc. There are generally four control methods, manual, semi-automatic, fully automatic, and adjustment.

(5) Heating/cooling system to modify this section The heating system is used to heat the barrel and injection nozzle. The barrel of the injection molding machine generally uses an electric heating ring as the heating device, which is installed on the outside of the barrel and is detected in sections with a thermocouple. The heat conducts heat conduction through the cylinder wall to supply the heat source for the plasticization of the material; the cooling system is mainly used to cool the oil temperature, too high oil temperature will cause a variety of faults, so the oil temperature must be controlled. The other location that needs to be cooled is adjacent to the discharge port of the material pipe to avoid melting of the material at the discharge port, which may cause the material to fail to be fed normally.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français