Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

Injection molding machines are used to produce plastic parts by injecting molten plastic into a mold. There are several types of injection molding machines, each designed for specific purposes. Here are the most common types:

1.Hydraulic injection molding machine: These machines use hydraulic power to generate the necessary pressure and force to inject the molten plastic into the mold. They are known for their high production capacity and accuracy.

2.Electric injection molding machine: These machines use electric motors to generate the necessary pressure and force to inject the molten plastic into the mold. They are known for their energy efficiency and high precision.

3.Hybrid injection molding machine: These machines combine hydraulic and electric systems to provide the benefits of both. They are known for their energy efficiency and high production capacity.

4.Two-shot injection molding machine: These machines are used to produce parts with two different colors or materials. They have two injection units that can inject two different materials into the mold.

5.Multi-component injection molding machine: These machines are used to produce parts with more than two materials. They have multiple injection units that can inject different materials into the mold.

6.Vertical injection molding machine: These machines are used for vertical

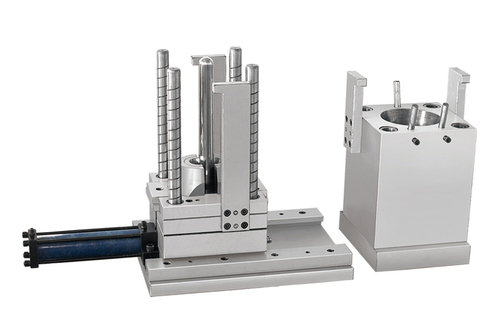

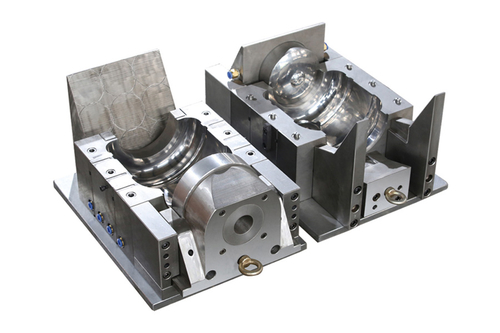

CSD-P Pet Preform Series Injection Molding Machine

CSD-P Pet Preform Series Injection Molding Machine

Professional PET screw and barrel improve preforms quality and finished

Products rate.Full closed cover available for internal cooling equipment.

Separate oil circular control supports synchronous mould open/close ejection function.

Back products belt conveyor available forthe preform cooling andthe connecting continuous

Automatic production line.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语