Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

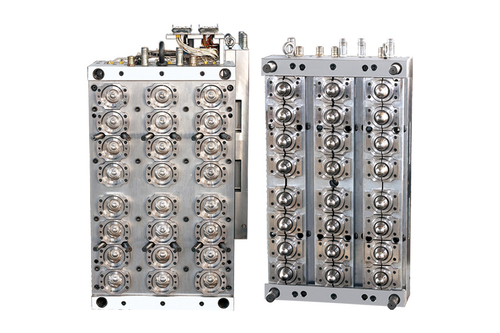

Injection molding machine is also known as injection molding machine or injection machine. It is the main molding equipment for making thermoplastic or thermosetting plastics into various shapes of plastic products using plastic molding dies. Divided into vertical, horizontal and all-electric. The injection molding machine can heat the plastic and apply high pressure to the molten plastic to make it shoot out and fill the mold cavity.

What are the characteristics of a vertical injection molding machine

1. The injection device and the clamping device are on the same vertical centerline, and the mold is opened and closed in the up and down direction. Its floor space is only about half of that of a horizontal machine, so it is about twice as productive when converted into floor space.

2. Easy to realize insert molding. Because the surface of the mold faces upwards, it is easy to insert and position the insert. Using the model with the lower template fixed and the upper template movable, and the combination of the belt conveyor device and the manipulator, fully automatic insert molding can be easily realized.

3. The weight of the mold is supported by the horizontal template to open and close up and down, and the phenomenon that the template cannot be opened and closed due to the gravity of the mold like a horizontal machine will not occur. It is conducive to maintaining the precision of machinery and molds for durability.

4. The cavity of each plastic part can be taken out by a simple manipulator, which is conducive to precision molding.

5. Generally, the surrounding mold clamping device is open, and it is easy to configure various automatic devices, which is suitable for the automatic molding of complex and delicate products.

6. The belt-drawing conveying device is easy to realize the installation through the middle of the mold, which is convenient to realize the automatic production of molding.

7. It is easy to ensure the resin fluidity in the mold and the consistency of the mold temperature distribution.

8. Equipped with rotating table, moving table and inclined table, etc., it is easy to realize insert molding and in-mold combination molding.

9. In the small batch trial production, the mold structure is simple, low cost, and easy to unload.

10. Having withstood the test of many earthquakes, the vertical machine has better seismic resistance than the horizontal machine due to its low center of gravity.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français