Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

To ensure proper design, close blow mold cooperation is required between the engineer-draftsman, the tool-builder, the molder, the supplier of raw material and, where styling is a factor, the artist-designer also. In the creation of the design of a molded article, the following steps should be followed carefully.On the basis of the characteristics required in the finished article, such as mechanical strength, electrical properties, chemical resistance, dimensional stability, heat-resistance and moisture-absorption, a selection is made of the type and grade of molding material which will best ensure the desired performance in service.The engineer-draftsman lists the fundamentals of the design, taking into consideration all functional requirements, and then makes a mechanical drawing of the piece as a component of the assembly.The artist-designer, using the fundamentals set forth by the engineer draftsman, incorporates color and form to meet the requirements of styling.

The engineer-draftsman, working in close collaboration with the artist-designer, converts the sketches and perspective drawings into accurately dimensioned detailed mechanical drawings of the piece to be produced.A machined model of the piece is produced, preferably from a molded block of the plastic selected. While the physical properties of a machined piece may not always be identical with those of a molded piece, nevertheless it is possible in many instances to conduct accelerated life tests on such a counterpart and thus judge the suitability of the proposed design as well as the physical characteristics of the plastic selected. Thus, costly time-consuming changes in design, re making of molds, and loss of production may frequently be avoided. A model will also enable the prospective user of the piece to see just what it will look like, and to check clearances and possible interferences in assembly with other parts. Also, experience has shown that models usually pay for themselves by showing where material might be saved, and shapes altered, to reduce costs of molds and of production.

We are now ready to consider the design of the article from the standpoint of the molding problems involved. What are the problems to be considered in the mold design? One of the most important steps preparatory to the decision on the type of mold to be used is a study of the flow behavior of the plastic selected for the article, during the flowing or formative period in the mold cavity. The mechanical, electrical and chemical properties of the molded article depend in part upon the controlled flow of the plastic. A study of the design of the article from the standpoint of the movement of the material in the mold cavity will reveal weaknesses in details of the design, such as poor knitting or welding of the material around protruding core pins and core sections. This is true in both thermoplastic and thermosetting materials. Consideration must be given to the length of time required to complete the flow, and a study of the path of flow and probable movement of the plastic will reveal ways of providing a streamlined flow. Care should be given to avoid heavy-sectioned areas which may entrap air, moisture and gas. Control of flow to avoid gas pockets in stagnant areas of mold cavities must receive serious study by the designer of the article, by the designer of the mold, and by the molder.

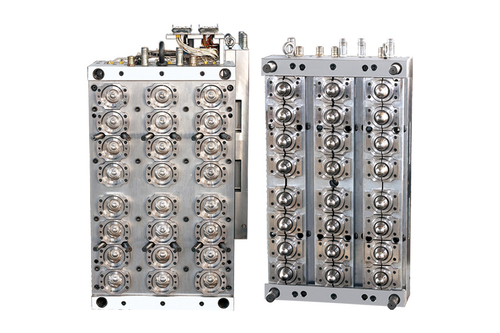

A single-cavity mold is built before proceeding with the construction of the multiple-cavity mold for production. Pieces produced from this experimental single-cavity mold are studied to determine whether proper provision has been made for molding shrinkage, dimensional accuracy, interchangeability in assembly, and serviceability.Generally, it is possible and practicable to design this single-cavity mold so that it may be used as one unit of the multiple-cavity production mold. In operating the single-cavity injection mold, and to get good dimensional reproduction comparisons between the production cavities and the initial test cavity, it is desirable to establish the time delay necessary for the plastic to arrive at the positions to be occupied by the number of cavities to be used in the finished mold.Therefore it is desirable to build the production mold base with all runners cut in place when testing the single cavity. Valuable information is obtained without substantially increasing the cost of the latter.The molder is also able to determine molding costs accurately, on the basis of actual operating cycles. In any event, the foregoing precautions should be taken to make sure that the product is correctly designed in every detail before proceeding with the construction of the production mold.Experience indicates that all too often, when these precautions are not taken, changes must be made after the molds have been completed and the piece is in production. This involves expensive alterations of the mold, as well as loss of production. The studies made possible through the use of a model and a single-cavity experimental mold do much to avoid this risk.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français