Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The process of blow moulding machine produces hollow objects such as glass bottles and plastic parts. This process is used to create hollow products and a variety of other objects. Here are a few examples of the products produced by this process. These products are used in the construction and manufacturing of various items, such as toys, jewelry, and appliances.A blow mold for extrusion is a process that is used to produce plastic bottles, jars, and jugs. It can process a wide range of plastics, including HDPE, PVC, PC, and PP. It also features multi-layer technologies, which improve product compatibility.The first commercial blow mold for extrusion was developed by Kautex in 1949. Reinold Hagen was looking for a way to retain the shape of plastic. He created the first extrusion blow molding machine to produce PVC parts. He was successful in this endeavor and soon the extrusion blow molding industry grew.

Blow molding is a cost-effective process for creating hollow objects. It is also a flexible process that can adapt to difficult spaces. It also allows for post-assembly of inserts. There is a free guide that can help you create a successful mold design.A successful stretch blow mold requires an understanding of the properties of the resin. Some resins have a higher stretch-ratio than others, such as PET which has a natural stretch-ratio of 16; PVC has a stretch-ratio of 6; and polystyrene can stretch up to 10 times. Cincinnati Milacron is another example, with a natural stretch-ratio of 9.Stretch blow molding is a versatile technology for the manufacture of a variety of products. One of its most popular applications is making PET bottles, which are widely used for water, juice, and sports drinks.

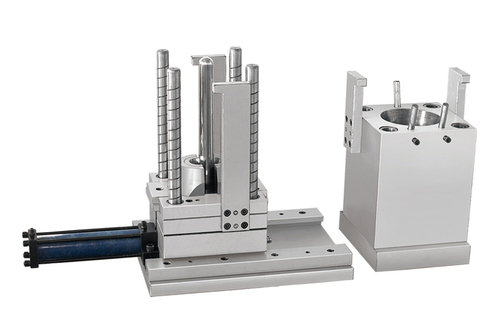

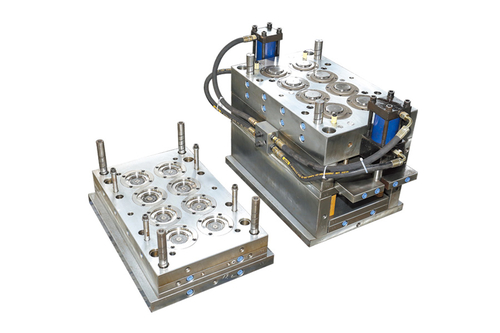

This technology was introduced in the 1970s and has become increasingly popular in recent years as a way to produce carbonated beverages. Stretch blow molding is also known for its ability to stretch materials in both the axial and hoop directions. This biaxial stretching improves the strength of the material and increases its barrier properties, while reducing the overall weight of the container.An injection blow molding system includes an injector nozzle and a parison cavity block. The injector nozzle is heated to a temperature similar to or just below the parison cavity temperature. This allows for precise alignment of the injector nozzle centerline with the parison cavity. The injector nozzle and the parison cavity block are held together by a restrictor plate.Injection moulding is a highly efficient process for large volume production.

It is a cost-effective method for producing thousands or millions of identical items. It can process a variety of materials, including metals, thermoplastic polymers, and glass. The injection mould is made of metal or plastic and is machined to mimic the features of the part being produced.Coextrusion in blow mold is a process that involves the coextrusion of more than one plastic layer. The advantage of this process over lamination is that the plastics do not have to be thick enough to stick together. This allows extremely thin layers to be coextrusions. Also, the coextrusions do not require individual layers to be self-supporting, which means cost savings are realized.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français