Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The jar preform mold has become a game-changer in the world of packaging, offering a versatile and efficient solution for producing PET (Polyethylene Terephthalate) jars. This innovative mold enables manufacturers to create customized jar preforms that cater to various industries, including food, beverages, cosmetics, and more. In this captivating description, we will delve into the features and benefits of the jar preform mold, highlighting its impact on packaging design, production efficiency, and product differentiation.

The jar preform mold unlocks a world of creativity and design freedom in packaging. With its customizable design, manufacturers can produce preforms for a wide range of jar sizes, shapes, and neck finishes. This flexibility allows for unique and eye-catching jar designs that resonate with target audiences. From sleek and modern to intricate and elegant, the jar preform mold empowers brands to stand out on store shelves and captivate consumers. The mold's versatility also accommodates the incorporation of features such as handles, tamper-evident seals, or custom embossing, further enhancing product differentiation and branding opportunities.

The jar preform mold optimizes efficiency and cost-effectiveness in packaging production. Its high-speed capabilities, combined with rapid mold changeovers, maximize production output and minimize downtime. The mold's advanced cooling system ensures shorter cycle times, enabling faster production cycles and increased productivity. Moreover, the ability to produce multiple jar preforms simultaneously within a single mold enhances efficiency and reduces tooling costs. The shared hot runner system enables precise control over material flow, minimizing material waste and optimizing resource utilization. The jar preform mold's efficiency not only streamlines the manufacturing process but also contributes to cost savings and improved profitability for packaging manufacturers.

The jar preform mold ensures high-quality and durable packaging solutions. Its precision engineering and advanced molding technology result in consistent wall thickness, uniform material distribution, and excellent dimensional accuracy in the preforms. This translates into jars that exhibit superior strength, rigidity, and product protection. The mold's robust construction and use of high-quality materials ensure longevity and reliability, allowing for long-term, repeatable production without compromising quality. The jar preform mold's commitment to quality packaging resonates with both manufacturers and consumers, fostering trust and brand loyalty.

The jar preform mold contributes to sustainability and environmental responsibility in packaging. By utilizing PET material, which is recyclable, the mold aligns with the growing demand for eco-friendly packaging solutions. The lightweight nature of PET jars reduces transportation emissions and energy consumption. Furthermore, the mold's efficiency in material utilization and the minimized waste through the shared hot runner system contribute to a more sustainable manufacturing process. The jar preform mold empowers brands to meet sustainability goals while delivering high-quality, visually appealing packaging solutions.

The jar preform mold represents a pivotal advancement in the packaging industry, offering manufacturers a platform to unleash their creativity, enhance efficiency, and differentiate their products. Experience the endless design possibilities, increased productivity, and sustainability benefits as you explore the transformative capabilities of the jar preform mold. Embrace the innovation and elevate your packaging solutions to new heights of customization, efficiency, and brand appeal.

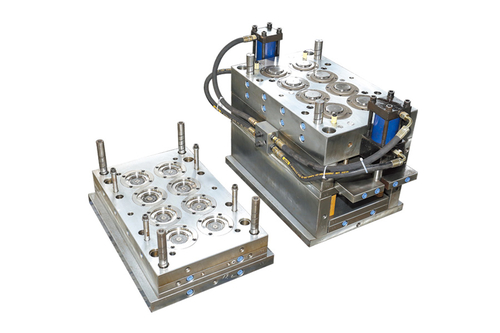

Jar Preform Mold

Jar Preform Mold

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français