Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the fast-evolving landscape of manufacturing, blow molding stands out as a vital technology for producing plastic products. This process, which creates hollow plastic parts, is experiencing a renaissance fueled by advancements in technology, sustainability initiatives, and a growing demand for lightweight and versatile packaging solutions. As industries continue to adapt to changing consumer preferences and regulatory standards, blow molding is positioned to play a pivotal role in shaping the future of manufacturing.

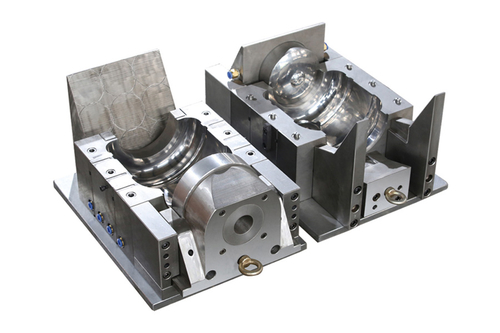

Blow molding is a manufacturing process that involves inflating hot plastic within a mold to create hollow objects. This method is commonly used for producing items such as bottles, containers, and automotive components. The process can be categorized into three primary types: extrusion blow molding, injection blow molding, and stretch blow molding, each offering unique advantages depending on the application.

Extrusion blow molding is often favored for its ability to produce large and complex shapes quickly, while injection blow molding excels in producing precise and intricate designs. Stretch blow molding, commonly used for PET bottles, enhances the clarity and strength of the final product. The versatility of blow molding makes it an essential technique across various sectors, including consumer goods, packaging, and automotive manufacturing.

The global blow molding market is experiencing significant growth, driven by several key trends. The increasing demand for lightweight packaging solutions, particularly in the food and beverage industry, is a major factor contributing to this growth. Manufacturers are seeking alternatives to traditional materials that can enhance product shelf life while reducing overall weight and shipping costs.

Moreover, the rise of e-commerce has heightened the need for durable and sustainable packaging. Blow-molded products, such as bottles and containers, are increasingly being designed with features that facilitate transportation and minimize environmental impact. This shift aligns with the growing consumer preference for eco-friendly products, prompting manufacturers to adopt sustainable practices in their production processes.

Technological advancements are revolutionizing the blow molding industry, enhancing efficiency, precision, and sustainability. Automated systems are becoming more prevalent, allowing for greater control over the manufacturing process and reducing human error. This automation not only improves productivity but also enables manufacturers to produce higher-quality products at a lower cost.

Additionally, advancements in materials science have led to the development of new polymers that offer improved performance characteristics. For instance, the introduction of bio-based and recycled materials is gaining traction, allowing manufacturers to reduce their carbon footprint while meeting consumer demand for sustainable products. These innovations are critical as companies strive to align with environmental regulations and corporate social responsibility initiatives.

Sustainability has emerged as a central theme in the blow molding industry. As consumers become more environmentally conscious, manufacturers are under pressure to adopt eco-friendly practices. Blow molding, in particular, has the potential to contribute to sustainability goals through the use of recyclable materials and energy-efficient processes.

Many companies are investing in technologies that enable the recycling of blow-molded products. Closed-loop systems, which allow for the reuse of post-consumer plastic, are being implemented to minimize waste and reduce reliance on virgin materials. Furthermore, energy-efficient blow molding machines are being developed to lower energy consumption during production, aligning with global efforts to combat climate change.

Despite the positive trends, the blow molding industry faces several challenges. Fluctuations in raw material prices can significantly impact production costs, making it essential for manufacturers to establish strong supplier relationships and diversify their sourcing strategies. Additionally, the increasing complexity of consumer demands requires companies to remain agile and innovative, adapting to changes in preferences and market conditions.

Moreover, regulatory pressures regarding environmental sustainability and safety standards are intensifying. Manufacturers must navigate these regulations while ensuring compliance, which can be a resource-intensive process. Adopting advanced technology and sustainable practices will be crucial for companies to stay competitive in this evolving landscape.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français