Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the competitive landscape of manufacturing technology, blow mold technology is at the forefront of innovation, offering groundbreaking solutions for a wide array of industries. This versatile and advanced manufacturing technique is revolutionizing how products are created, from everyday consumer goods to complex industrial components. As manufacturers seek new ways to improve efficiency, sustainability, and product quality, the blow mold process is proving to be an indispensable tool in the modern production environment.

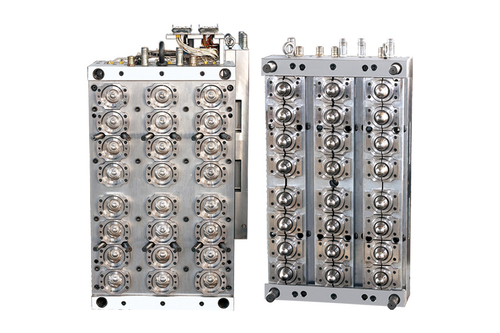

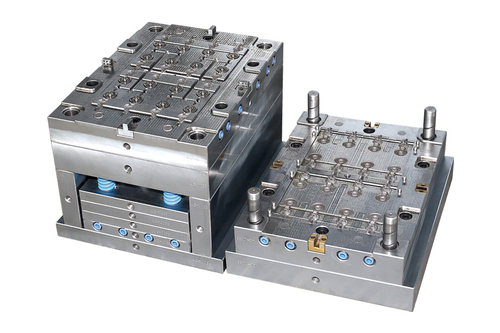

At its core, blow mold technology involves shaping molten plastic into hollow objects through the application of air pressure. This process is distinguished by its ability to produce intricate, high-quality products with a wide range of applications. The significance of blow mold technology lies in its capacity to create durable, lightweight, and cost-effective products that meet the demands of both industrial and consumer markets.

One of the notable advancements in blow mold technology is the development of more energy-efficient machinery. Modern blow mold machines are designed with advanced features that reduce energy consumption and operational costs. These innovations include energy-saving hydraulic systems, high-efficiency air compressors, and intelligent control systems that optimize the molding process. By integrating these cutting-edge technologies, manufacturers are able to produce high-quality products while minimizing their environmental impact and reducing production costs.

Another exciting development in blow mold technology is the introduction of new materials and techniques. Traditional blow mold processes often utilized single-layer plastic, but recent advancements have enabled the creation of multi-layered and co-extruded products. These innovations allow for the production of more complex items with enhanced properties, such as improved barrier performance, increased strength, and greater aesthetic appeal. The ability to incorporate different materials into a single product through blow mold techniques opens up new possibilities for designers and engineers in various industries.

The versatility of blow mold technology is evident in its wide range of applications. From plastic bottles and containers to automotive parts and industrial components, the blow mold process can be tailored to meet the specific requirements of diverse products. For instance, in the consumer goods sector, blow mold technology is used to produce everything from beverage bottles to household cleaning products. In the automotive industry, blow mold techniques are employed to create lightweight and durable components for vehicles, contributing to both performance and fuel efficiency. This broad applicability underscores the importance of the blow mold process in modern manufacturing.

Sustainability is a key focus for the future of blow mold technology. As environmental concerns become increasingly prominent, the blow mold industry is responding with innovations aimed at reducing waste and improving recycling practices. New techniques for reclaiming and reusing plastic materials are being developed to minimize the environmental footprint of the manufacturing process. Additionally, the use of biodegradable plastics and other eco-friendly materials in blow mold production is gaining traction as part of a broader effort to promote sustainability in manufacturing.

One of the key benefits of blow mold technology is its ability to produce products with consistent quality and precision. Modern blow mold machines are equipped with advanced sensors and automated systems that ensure every product meets stringent quality standards. This level of precision is essential for producing components that must adhere to exact specifications, such as those used in medical devices, aerospace applications, and high-end consumer products. The reliability of blow mold technology helps manufacturers maintain high standards of quality and performance across a wide range of applications.

The blow mold industry is also experiencing significant growth in the global market. As demand for plastic products continues to rise, manufacturers are investing in blow mold technology to stay competitive. The expansion of the industry is driven by the increasing use of plastic products in various sectors, including packaging, automotive, and consumer goods. The global market for blow mold technology is expected to continue growing, with new opportunities for innovation and expansion in emerging markets.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français