Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

As industries across the globe seek more efficient and sustainable packaging solutions, the spotlight is increasingly on blow molded bottles. This versatile packaging option has become a cornerstone in various sectors, from food and beverage to pharmaceuticals and personal care. The growing popularity of blow molded bottles underscores their importance in the modern packaging landscape, driven by innovations in materials and manufacturing processes that offer both functional benefits and environmental advantages.

Blow molded bottles are created using a process called blow molding, which involves inflating a heated plastic tube, or parison, into a mold to form a bottle shape. This technique is favored for its ability to produce lightweight, durable, and cost-effective containers in high volumes. The blow molding process allows for precise control over the bottle’s design, including its shape, size, and wall thickness, making it an ideal choice for various applications.

In recent years, there has been a significant shift towards sustainability in packaging. Blow molded bottles are at the forefront of this trend, with many manufacturers adopting eco-friendly practices and materials. Recycled plastics are increasingly used in the production of blow molded bottles, reducing the need for virgin materials and minimizing environmental impact.

Furthermore, innovations in biodegradable and compostable plastics are making their way into the blow molding industry. These materials break down more easily in the environment, offering a more sustainable alternative to traditional plastics. The move towards eco-friendly blow molded bottles reflects a broader industry commitment to reducing plastic waste and promoting circular economy principles.

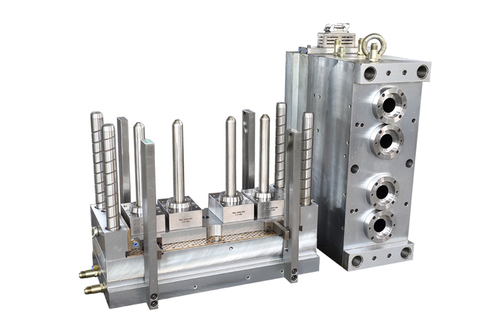

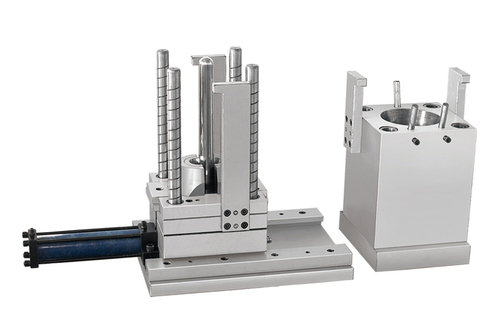

Advancements in blow molding technology are revolutionizing the production of blow molded bottles, enhancing both efficiency and quality. One significant development is the use of advanced automation and robotics in the manufacturing process. Automated systems improve precision, reduce production time, and lower labor costs, to more consistent and high-quality bottles.

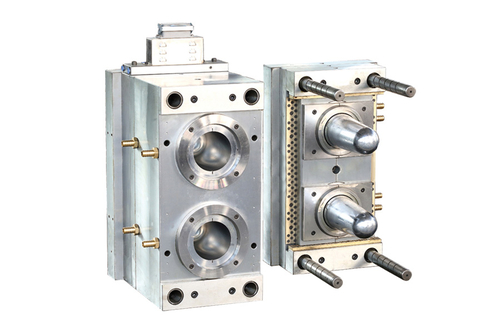

Additionally, innovations in mold design and materials have contributed to the improved performance of blow molded bottles. New mold technologies enable the creation of complex bottle shapes and features, such as ergonomic handles and tamper-evident closures, that meet the evolving needs of consumers and industries.

Another technological breakthrough is the integration of multi-layer blow molding. This process allows for the production of bottles with multiple layers, combining different materials to enhance functionality. For example, multi-layer bottles can offer improved barrier properties, protecting contents from oxygen and moisture and extending shelf life.

Blow molded bottles are used in a wide range of applications due to their versatility and benefits. In the beverage industry, these bottles are commonly used for soft drinks, water, and juices. Their lightweight nature and durability make them suitable for handling and transportation, while their ability to be molded into various shapes and sizes meets diverse packaging needs.

In the pharmaceutical sector, blow molded bottles are employed for packaging medications and health supplements. The ability to produce bottles with tamper-evident features and precise dosing mechanisms enhances safety and convenience for consumers.

The personal care and cosmetics industry also relies on blow molded bottles for packaging products such as lotions, shampoos, and conditioners. The customization options available with blow molding, including unique bottle shapes and decorative elements, allow brands to differentiate their products and attract consumers.

Regulatory changes are shaping the future of blow molded bottles as governments and organizations implement stricter guidelines on packaging materials and recycling. In response to these regulations, manufacturers are investing in new technologies and materials to ensure compliance and meet consumer expectations for sustainable packaging solutions.

For instance, many regions are introducing bans on single-use plastics and encouraging the use of recyclable and compostable materials. These regulations drive the adoption of more sustainable practices in the production of blow molded bottles, prompting the industry to innovate and adapt to evolving standards.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français