Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the ever-evolving landscape of manufacturing, the blow mold has emerged as a critical tool in producing high-quality plastic products. From packaging to automotive parts, the influence of blow mold technology extends across various industries, reflecting its versatility and innovation. As the demand for efficient, precise, and sustainable manufacturing processes grows, the blow mold is at the forefront of these advancements, shaping the future of production.

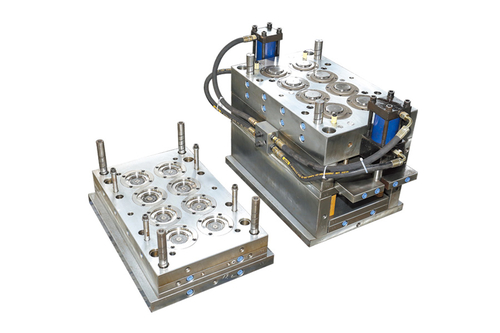

The blow mold process, a subset of molding techniques, is essential for creating hollow plastic items. This method involves inflating a heated plastic parison (a preform) within a mold cavity to form the desired shape. The blow mold ensures that the plastic conforms to the mold's design, resulting in products with consistent dimensions and quality. The process is favored for its ability to produce lightweight and durable containers, making it ideal for high-volume manufacturing.

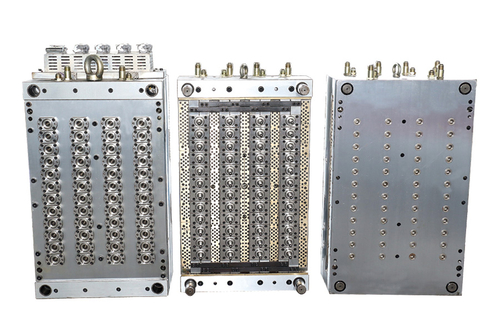

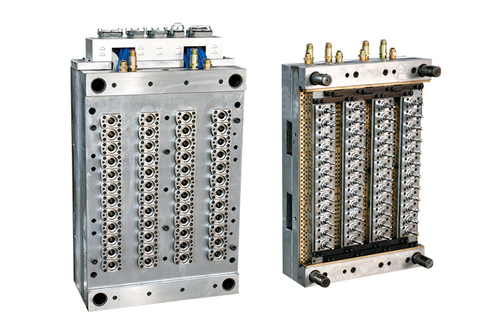

Recent developments in blow mold technology are revolutionizing the manufacturing sector. One significant advancement is the incorporation of advanced materials in mold construction. Modern blow molds are increasingly made from high-performance alloys and composites, which offer improved durability, thermal conductivity, and resistance to wear. These materials enhance the longevity of the mold and reduce maintenance requirements, to more efficient and cost-effective production.

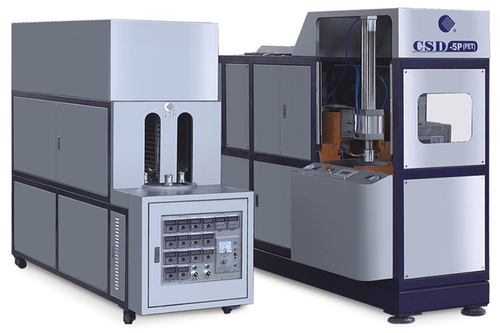

Automation and robotics are also transforming the blow mold process. Automated systems equipped with precision sensors and control mechanisms allow for greater accuracy and consistency in manufacturing. This integration reduces the potential for human error, speeds up production times, and ensures high-quality outcomes. Additionally, real-time monitoring and data analysis enable manufacturers to optimize the blow mold process, identify issues early, and make adjustments to maintain performance.

As environmental concerns become more pressing, the role of sustainability in manufacturing is gaining prominence. The blow mold industry is responding to these concerns with innovative practices and materials. One major trend is the use of recycled plastics in blow molding. By incorporating recycled materials, manufacturers can reduce their reliance on virgin plastics and minimize waste.

The development of biodegradable and compostable plastics is another significant advancement. These materials decompose more quickly in the environment, offering a more sustainable alternative to traditional plastics. The adaptation of blow molds to handle these new materials is crucial in supporting the industry's shift towards greener practices.

Design improvements in blow molds also contribute to sustainability. Enhanced cooling systems, optimized mold designs, and energy-efficient technologies reduce energy consumption and material waste during production. These advancements align with broader industry goals of reducing the carbon footprint and promoting eco-friendly manufacturing practices.

The versatility of the blow mold process makes it suitable for a wide range of applications. In the packaging industry, blow molds are used to produce bottles and containers for beverages, chemicals, and personal care products. The ability to create lightweight, durable, and aesthetically appealing containers is a significant advantage in this sector.

The automotive industry also relies on blow molds for manufacturing various components, including fuel tanks, air ducts, and interior parts. The strength and flexibility of blow-molded components contribute to the performance and safety of vehicles.

In the consumer goods sector, blow molds are employed to create a variety of products, such as toys, household items, and sporting equipment. The capacity to produce complex shapes and designs with high precision makes the blow mold an invaluable tool in this industry.

Looking ahead, the future of the blow mold industry is poised for continued innovation and growth. Emerging technologies, such as 3D printing and advanced materials science, are expected to influence the development of new blow mold designs and manufacturing techniques. These innovations will expand the capabilities of blow molding, allowing for more intricate and customized products.

The emphasis on sustainability will also drive future developments in the blow mold industry. The adoption of eco-friendly materials, improved recycling practices, and the development of closed-loop systems will play a crucial role in shaping the industry's direction. Manufacturers will need to adapt to these changes to meet evolving consumer expectations and regulatory requirements.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français