Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the dynamic landscape of modern manufacturing, blow mold technology stands out as a critical innovation that has revolutionized the production of plastic products. From everyday household items to intricate industrial components, blow mold techniques have enabled manufacturers to create a wide array of products with precision, efficiency, and versatility. This article delves into the evolution of blow mold technology, its applications, and its significant impact on the manufacturing industry.

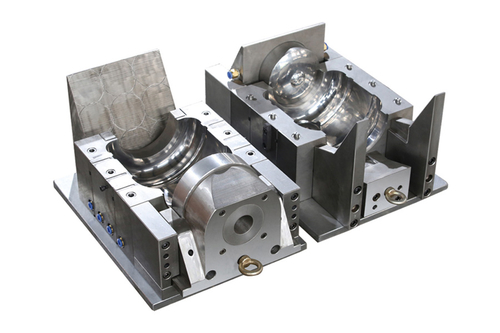

Blow mold technology, at its core, involves the process of inflating heated plastic into a mold cavity, creating a hollow product. This method is particularly effective for producing containers such as bottles, jars, and jugs, but its applications extend far beyond simple packaging solutions. The process is divided into three primary types: extrusion blow molding, injection blow molding, and stretch blow molding, each offering unique advantages for different product requirements.

Extrusion blow molding is one of the commonly used methods in the blow mold industry. In this process, molten plastic is extruded into a tube (parison), which is then clamped into a mold and inflated with air to take the shape of the mold cavity. This technique is ideal for producing large volumes of hollow products, such as plastic bottles and containers. The versatility of extrusion blow molding allows for the creation of complex shapes and sizes, catering to various industrial and consumer needs.

Injection blow molding, on the other hand, is a method that combines the precision of injection molding with the efficiency of blow molding. In this process, molten plastic is injected into a preform mold to create a preform, which is then transferred to a blow mold where it is inflated to its final shape. This technique is particularly useful for producing small, high-precision containers such as pharmaceutical bottles and cosmetic packaging. The dimensional accuracy and surface finish achieved through injection blow molding make it a preferred choice for high-quality applications.

Stretch blow molding is a more advanced variation of the blow mold process, primarily used for creating lightweight, durable containers. This method involves stretching the preform both axially and radially during the blowing process, which aligns the polymer chains and enhances the strength of the final product. Stretch blow molding is commonly used in the production of PET bottles for beverages, offering clarity and impact resistance. The ability to produce thin-walled, high-strength containers with minimal material usage makes stretch blow molding an economically and environmentally advantageous choice.

The advancements in blow mold technology have been driven by the continuous demand for innovative, cost-effective manufacturing solutions. Modern blow mold machines are equipped with sophisticated control systems, enabling precise regulation of temperature, pressure, and other critical parameters. These enhancements have significantly improved the quality and consistency of blow molded products, reducing waste and increasing production efficiency. Additionally, the integration of automation and robotics has streamlined the blow mold process, further boosting productivity and reducing labor costs.

One of the significant impacts of blow mold technology is its contribution to sustainability in manufacturing. The ability to produce lightweight, recyclable plastic products with minimal material usage aligns with the growing emphasis on environmental responsibility. Many blow molded products, such as PET bottles, are widely recycled, reducing the environmental footprint of plastic production. Furthermore, advancements in biodegradable and bio-based plastics are expanding the potential for sustainable blow mold applications, offering eco-friendly alternatives to traditional petrochemical-based plastics.

The versatility of blow mold technology extends to various industries beyond packaging. In the automotive sector, blow molded components are used for fuel tanks, air ducts, and other critical parts, offering a balance of strength and weight reduction. The medical industry relies on blow molded products for items such as medical device housings and fluid containers, where precision and hygiene are paramount. Even the toy industry benefits from blow mold technology, producing durable, lightweight toys that withstand rigorous use.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语