Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the manufacturing industry, the High-Speed Preform Production Line stands as a crucial element in optimizing production processes for various industries, particularly in the packaging sector. These innovative production lines have revolutionized the efficiency and speed at which preforms, essential components in packaging, are manufactured.

The appeal of High-Speed Preform Production Lines lies in their ability to significantly enhance production capabilities. These lines integrate advanced technology and automation to streamline the manufacturing of preforms, essential building blocks for plastic bottles and containers used in beverage, food, and personal care packaging.

Manufacturers have embraced these high-speed production lines for their capacity to meet increasing demands. "The High-Speed Preform Production Line has revolutionized our manufacturing process," shared a production manager. "It has allowed us to scale up production while maintaining precision and quality."

One of the key advantages of these production lines is their remarkable speed and efficiency. Equipped with cutting-edge machinery and automation systems, they can produce preforms at a significantly higher rate compared to traditional methods, thereby boosting productivity.

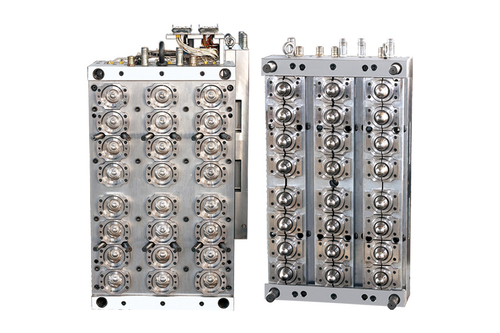

Moreover, these production lines offer precision and consistency in manufacturing preforms. Advanced control systems ensure uniformity in size, weight, and quality of preforms, meeting strict industry standards and minimizing inconsistencies in the final product.

The integration of automation in High-Speed Preform Production Lines contributes to reducing labor requirements and operational costs. Automated processes, from material feeding to molding and packaging, streamline the production workflow, optimizing efficiency and resource utilization.

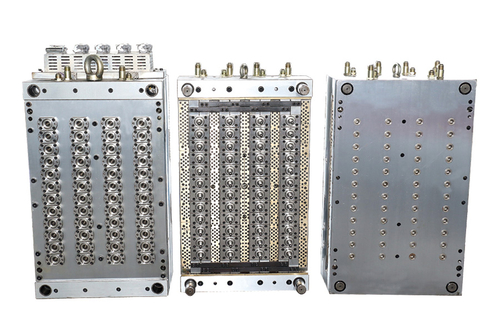

Furthermore, the versatility of these production lines allows for customization and adaptation to various preform designs and specifications. Manufacturers can adjust settings and molds to produce preforms tailored to specific packaging needs, offering flexibility in design and production.

The efficiency of High-Speed Preform Production Lines plays a significant role in reducing lead times and meeting market demands promptly. The accelerated production rate ensures a steady supply of preforms, enabling manufacturers to respond swiftly to consumer needs and market fluctuations.

In an era where efficiency and productivity are paramount, these production lines play a pivotal role in the packaging industry. Their contribution to accelerating production without compromising quality signifies a shift towards optimizing manufacturing processes.

As industries prioritize efficiency and scalability, the adoption of High-Speed Preform Production Lines continues to grow. Their ability to improve output while maintaining precision underscores their importance in ensuring a competitive edge in the packaging market.

In a world where manufacturing meets technology, these production lines represent the convergence of innovation and efficiency. Their role in enhancing productivity and meeting the increasing demand for preforms signifies a dedication to advancing manufacturing capabilities in the packaging sector.

The utilization of High-Speed Preform Production Lines marks a transformative step in manufacturing efficiency. Their impact on streamlining production, enhancing quality, and meeting market demands underscores their significance in driving advancements within the packaging industry.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语