Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

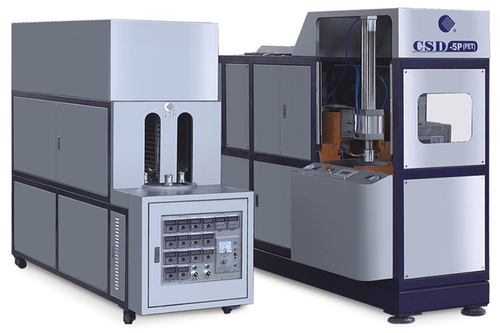

In the world of packaging, innovation is key to staying ahead of the curve. Enter PET jar preform molds, the unsung heroes behind the sleek and versatile PET jars that have become a staple in industries ranging from food and beverage to pharmaceuticals and cosmetics. These molds play a crucial role in the production of PET jars, shaping them into the perfect containers for storing a wide range of products securely and efficiently.

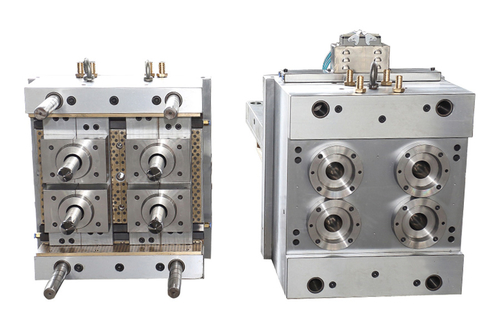

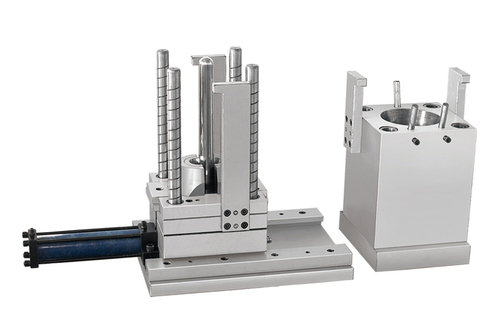

But what exactly are PET jar preform molds, and why are they causing such a stir in the packaging industry? Put simply, PET (polyethylene terephthalate) jar preform molds are precision-engineered tools used to create the preforms that serve as the building blocks for PET jars. These preforms are then heated and stretched to form the final shape of the jar, resulting in a lightweight yet durable container that is ideal for a variety of applications.

"The beauty of PET jar preform molds lies in their versatility," explains packaging expert Lisa. "Whether you're packaging beverages, condiments, personal care products, or anything in between, PET jars offer the perfect combination of functionality and aesthetics."

One of the key advantages of PET jar preform molds is their ability to produce jars in a wide range of shapes and sizes. From small, single-serve containers to large, family-sized jars, these molds can be customized to meet the unique needs of each product and brand. Plus, PET jars are transparent, allowing consumers to see the contents clearly, which is especially important for products where visual appeal is a key selling point.

But it's not just about looks—PET jars offer a host of practical benefits as well. Unlike traditional glass jars, PET jars are lightweight and shatterproof, making them ideal for shipping and handling. They're also resistant to impact, moisture, and temperature fluctuations, ensuring that your products stay fresh and intact from production to consumption.

For manufacturers, PET jar preform molds offer a cost-effective solution for packaging production. The molds themselves are durable and long-lasting, requiring minimal maintenance and offering high precision and consistency in production. Plus, PET jars are fully recyclable, making them an environmentally friendly choice for brands looking to reduce their carbon footprint.

"The demand for PET jars has been steadily increasing in recent years, and PET jar preform molds are a crucial part of meeting that demand," says packaging industry analyst John. "With their efficiency, versatility, and sustainability, PET jars offer a winning combination for brands looking to stand out on the shelf."

But it's not just about the bottom line—PET jars are also winning over consumers with their convenience and ease of use. With features like screw-top lids and wide mouths for easy filling and pouring, PET jars are a practical choice for busy households and on-the-go lifestyles. Plus, they're microwave and dishwasher safe, offering added convenience for consumers.

From condiments and sauces to snacks and beverages, PET jars are making their mark across a wide range of product categories. And with PET jar preform molds driving innovation and efficiency in production, the future looks bright for this versatile packaging solution. So whether you're a manufacturer looking to streamline your packaging process or a consumer in search of convenience and quality, PET jars are sure to make a lasting impression.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français