Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the ever-evolving landscape of manufacturing, innovation continues to shape the way products are made and distributed. One industry experiencing a significant transformation is beverage packaging, with automatic PET bottle blowing machine factories emerging as key players in the production process. These cutting-edge facilities are revolutionizing the way PET bottles are manufactured, offering efficiency, precision, and scalability like never before.

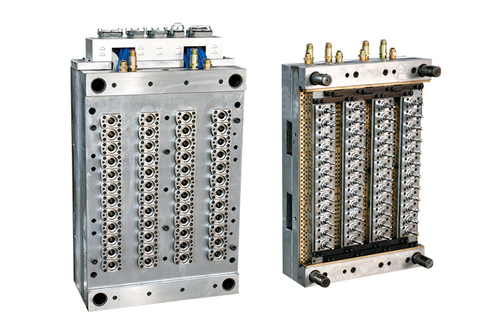

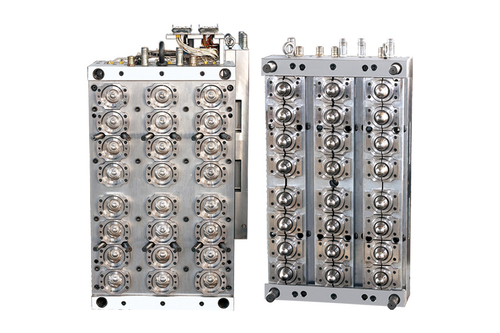

Automatic PET bottle blowing machines are advanced pieces of equipment designed to produce PET (polyethylene terephthalate) bottles used for packaging various beverages, including water, soda, juice, and sports drinks. These machines utilize a process called blow molding, where preforms—small tubes of PET resin—are heated and stretched into the desired bottle shape using compressed air. While PET bottle blowing machines have been around for decades, recent advancements in technology have led to the development of fully automated systems capable of high-speed production with minimal human intervention.

The emergence of automatic PET bottle blowing machine factories represents a significant shift in the beverage packaging industry. These state-of-the-art facilities are equipped with advanced machinery and robotic systems that can handle every aspect of the bottle manufacturing process, from heating and stretching the preforms to trimming and inspecting the finished bottles. As a result, production efficiency is maximized, and the risk of human error is minimized, leading to higher-quality products and increased productivity.

One of the primary advantages of automatic PET bottle blowing machine factories is their ability to produce bottles in a wide range of shapes, sizes, and designs. Whether it's a standard 500ml water bottle or a custom-shaped container for a specialty beverage, these machines can accommodate diverse production requirements with ease. This flexibility allows beverage companies to differentiate their products in the market and respond quickly to changing consumer preferences.

Furthermore, automatic PET bottle blowing machine factories offer scalability and versatility, making them suitable for both small-scale startups and large-scale beverage manufacturers. With the ability to adjust production volumes and bottle specifications on the fly, these facilities can adapt to fluctuating market demands and seasonal variations in consumption patterns. This agility is essential for maintaining a competitive edge in the fast-paced beverage industry.

In addition to their production capabilities, automatic PET bottle blowing machine factories also prioritize sustainability and environmental responsibility. PET is a highly recyclable material, and many of these facilities incorporate recycling and waste reduction initiatives into their operations. By optimizing material usage, minimizing energy consumption, and implementing closed-loop recycling systems, these factories strive to minimize their environmental footprint and contribute to a more sustainable future.

The growing popularity of automatic PET bottle blowing machine factories is also driving innovation in packaging design and materials. With advancements in PET technology and bottle manufacturing techniques, beverage companies have more options than ever when it comes to packaging their products. From lightweight and eco-friendly bottles made with recycled PET to innovative designs that enhance shelf appeal and consumer convenience, the possibilities are endless.

Despite their many advantages, automatic PET bottle blowing machine factories are not without challenges. The initial investment required to set up a fully automated production facility can be substantial, particularly for small and medium-sized enterprises. Additionally, ensuring the proper maintenance and calibration of the machinery is essential to prevent downtime and ensure consistent product quality.

Nevertheless, the benefits of automatic PET bottle blowing machine factories far outweigh the challenges for many beverage companies. By investing in state-of-the-art production facilities, manufacturers can streamline their operations, reduce costs, and deliver high-quality products to consumers more efficiently than ever before. As the demand for bottled beverages continues to grow worldwide, these innovative factories are poised to play a central role in shaping the future of beverage packaging for years to come.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français