Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the realm of container manufacturing, where attention to detail is crucial, the Cap Mold stands as a beacon of innovation, reshaping the landscape of container closure technology. This specialized mold plays a pivotal role in creating the perfect cap, ensuring a secure and effective seal for a wide range of containers. Let's explore the cutting-edge features of the Cap Mold and its transformative impact on the packaging industry.

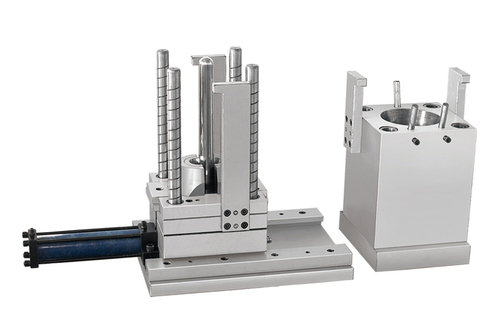

The defining feature of the Cap Mold lies in its precision molding capabilities, specifically designed to create high-quality caps for containers. Unlike generic molds, the Cap Mold is engineered with intricate details that cater to the specific requirements of container closure technology. This level of precision ensures that each cap produced meets stringent quality standards, providing an effective and reliable sealing solution.

One of the standout features of this mold is its ability to produce caps with consistent and uniform characteristics. The precision engineering of the Cap Mold ensures that each cap is identical, eliminating variations in size, shape, and functionality. This uniformity is critical in industries such as food and beverage, pharmaceuticals, and cosmetics, where product integrity and safety are paramount.

The versatility of the Cap Mold extends to its applicability across a diverse range of materials. Whether molding caps from plastic, metal, or other materials, the mold accommodates the specific requirements of different industries. This flexibility allows manufacturers to customize caps based on the unique properties of the container and the contents it will secure.

Manufacturers investing in the Cap Mold benefit from its ability to create caps with intricate designs and features. Advanced models may include capabilities for molding tamper-evident features, child-resistant closures, and unique branding elements. This customization adds value to the final product, contributing to brand identity and consumer satisfaction.

In an era where sustainability is a driving force in packaging, the Cap Mold plays a role in creating eco-friendly caps. The mold can be designed to accommodate the use of recycled materials or alternative sustainable resources, aligning with the growing demand for environmentally conscious packaging solutions.

The success stories from manufacturers adopting the Cap Mold underscore its transformative impact on the industry. Emily Roberts, a packaging engineer, shares, "The precision of the Cap Mold has elevated the quality of our closures. We can confidently deliver caps that not only meet industry standards but also enhance the overall consumer experience."

As we navigate the ever-evolving landscape of packaging technology, the Cap Mold emerges as a symbol of precision and customization. In a world where container closure technology is a critical component of product safety and presentation, this mold sets the stage for a new era of cap manufacturing. It's not just a mold; it's a catalyst for elevating packaging processes to unprecedented levels of accuracy and customization. The transformative power of the Cap Mold is reshaping the future of container closure technology, offering manufacturers a pathway to excellence in the production of caps that meet the diverse needs of modern packaging.

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语