Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the realm of packaging manufacturing, precision and innovation are driving forces behind the production of high-quality products. At the forefront of this innovation stands the PET preform mold, a critical component in the creation of PET (polyethylene terephthalate) bottles and containers. With its advanced design, meticulous craftsmanship, and commitment to excellence, the PET preform mold continues to revolutionize the packaging industry and pave the way for new possibilities in product design and manufacturing processes.

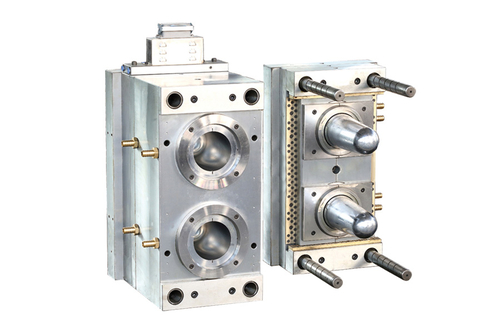

At its core, the PET preform mold serves as the foundation for the production of PET bottles and containers, shaping the preforms that will ultimately become the final product. Crafted with precision and attention to detail, these molds are engineered to exact specifications to ensure consistent and uniform preform quality. From beverage bottles to household products, PET preform molds play a vital role in delivering packaging solutions that meet the highest standards of performance and reliability.

One of the defining features of PET preform molds is their versatility and adaptability to various manufacturing processes. Whether used in injection molding, stretch blow molding, or other production methods, these molds can be customized to accommodate different bottle shapes, sizes, and designs. This flexibility enables manufacturers to create a diverse range of packaging solutions to meet the unique needs of their customers and industries.

Moreover, PET preform molds are designed with precision engineering and advanced technology to optimize performance and efficiency in the manufacturing process. Using state-of-the-art CAD/CAM software, designers meticulously craft mold cavities with precise dimensions and tolerances, ensuring consistent preform quality and minimizing material waste. CNC machining and EDM (electrical discharge machining) are then employed to fabricate the mold components with unparalleled accuracy, resulting in molds that deliver exceptional performance and longevity.

In addition to their precision engineering, PET preform molds are also engineered with sustainability in mind, reflecting the growing demand for eco-friendly packaging solutions. Manufacturers are incorporating features into mold designs that enable the production of lightweight preforms, reducing material usage and environmental impact. Additionally, advancements in energy-efficient heating technologies and hot runner systems are being implemented to minimize energy consumption and waste during the molding process, further enhancing the sustainability credentials of PET preform molds.

Furthermore, PET preform molds are driving innovation and creativity in packaging design, empowering brands to create distinctive and eye-catching bottles and containers that resonate with consumers. From sleek and modern designs to nostalgic and vintage-inspired aesthetics, PET preform molds offer endless possibilities for product differentiation and brand expression. By leveraging the capabilities of PET preform molds, brands can create packaging solutions that stand out on store shelves and leave a lasting impression on consumers.

As consumer preferences continue to evolve, PET preform molds are poised to play an increasingly important role in shaping the future of packaging manufacturing. Manufacturers are investing in research and development efforts to further enhance the efficiency, sustainability, and versatility of PET preform molds, driving continuous improvement and innovation in the industry. By embracing the latest advancements in technology and sustainability practices, PET preform molds are paving the way for a more sustainable, efficient, and creative future in packaging manufacturing.

In conclusion, PET preform molds are revolutionizing the packaging industry, driving innovation, efficiency, and sustainability in manufacturing processes. With their advanced design, precision engineering, and commitment to excellence, these molds are reshaping the landscape of packaging solutions and opening up new possibilities for product design and differentiation. As demand for sustainable and innovative packaging solutions continues to rise, PET preform molds will continue to play a central role in driving positive change and shaping the future of packaging manufacturing worldwide.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français