Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the dynamic world of manufacturing, where innovation is the cornerstone of progress, the CSD-W-S Injection Molding Machine has emerged as a revolutionary force. This cutting-edge machine, designed for versatility and precision, is reshaping the landscape of injection molding, setting new standards for efficiency, adaptability, and sustainability.

The CSD-W-S Injection Molding Machine is not just a piece of equipment; it's a testament to the continual evolution of manufacturing technology. Boasting a range of features tailored for the demands of modern production, this machine is a powerful tool in the hands of manufacturers seeking to stay ahead in an ever-changing industry.

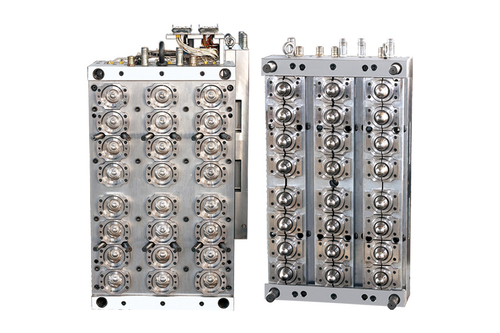

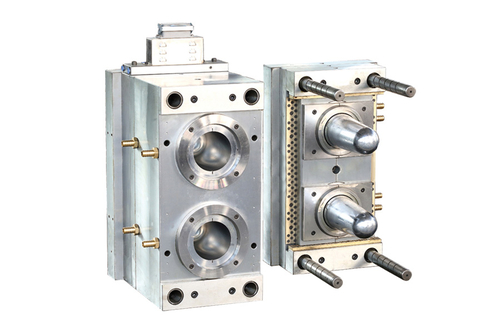

One of the standout features of the CSD-W-S series is its innovative dual-platen design. Unlike traditional single-platen machines, this design enhances stability and precision in the molding process. The dual-platen system ensures uniform distribution of clamping force, resulting in higher accuracy and consistency in the production of complex components. This level of precision is crucial in industries where even slight variations can impact product quality.

The adaptability of the CSD-W-S series is a game-changer. Equipped with a multi-material injection unit, the machine can handle a variety of raw materials, opening up possibilities for manufacturing intricate and multi-component products. Manufacturers can easily switch between materials without compromising efficiency, making the machine a versatile solution for diverse production needs.

Speed is a decisive factor in meeting the demands of modern manufacturing, and the CSD-W-S series excels in this aspect. The machine's high-speed injection and clamping mechanisms significantly reduce cycle times, leading to enhanced overall production efficiency. This rapid processing capability ensures that manufacturers can keep up with tight schedules and ever-increasing production targets.

Energy efficiency is a key consideration in today's manufacturing landscape, and the CSD-W-S series addresses this concern proactively. The machine incorporates advanced servo motor technology, optimizing energy consumption by adjusting power usage based on the actual needs of the process. This not only contributes to a reduction in operational costs but also aligns with the growing emphasis on sustainable and eco-friendly manufacturing practices.

Versatility is a defining feature of the CSD-W-S Injection Molding Machine. With a user-friendly control interface and customizable settings, manufacturers have the flexibility to adapt the machine to a diverse range of products. The ability to switch between molds and configurations seamlessly enhances production efficiency and allows for quick responses to market demands.

Real-world applications of the CSD-W-S Injection Molding Machine have showcased its transformative impact on manufacturing processes. In a recent case study, a company reported a substantial increase in productivity after adopting the CSD-W-S series. The machine's dual-platen design and multi-material capabilities enabled the production of intricate components with heightened precision, meeting the stringent quality standards of the industry.

However, the adoption of advanced technology, such as the CSD-W-S series, does pose challenges for manufacturers. The initial investment in cutting-edge machinery can be a significant barrier, particularly for smaller businesses. Additionally, the need for a skilled workforce to operate and maintain the machine highlights the importance of ongoing training and education within the manufacturing sector.

In conclusion, the CSD-W-S Injection Molding Machine stands at the forefront of the manufacturing revolution. Its combination of a dual-platen design, multi-material capabilities, high-speed processing, energy efficiency, and versatility positions it as an industry leader. As manufacturers navigate the complexities of modern production, the CSD-W-S series stands as a beacon of innovation, providing a pathway to enhanced efficiency, adaptability, and sustainability in injection molding processes.

CSD-W-S Injection Molding Machine

CSD-W-S Injection Molding Machine

英语

英语 中文简体

中文简体 俄语

俄语 西班牙语

西班牙语 法语

法语