Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In the intricate world of packaging manufacturing, jar PET preform mold manufacturers stand at the forefront, driving innovation, precision, and reliability in the production of packaging solutions. These specialized manufacturers play a pivotal role in designing, engineering, and producing high-quality molds that shape PET (polyethylene terephthalate) plastic into preform blanks for jars, empowering companies to create containers that meet the highest standards of performance, efficiency, and sustainability. With their expertise, dedication, and commitment to excellence, jar PET preform mold manufacturers are instrumental in shaping the future of the packaging industry and driving advancements in packaging design and production.

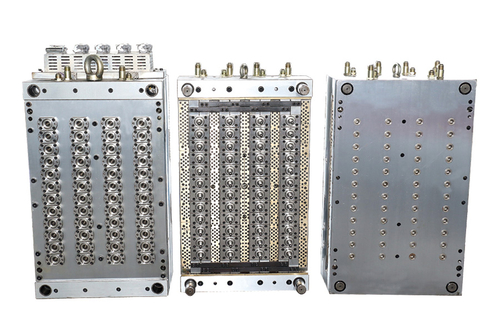

Jar PET preform mold manufacturers are renowned for their precision engineering and meticulous craftsmanship in creating molds that meet the exacting standards of the packaging industry. Leveraging advanced CAD (computer-aided design) software, precision machining technologies, and innovative materials, these manufacturers design molds with intricate cavity designs, precise dimensions, and smooth surface finishes. This precision is essential for ensuring the consistent production of preform blanks that meet the stringent requirements of companies in industries such as food and beverage, personal care, and household products.

Moreover, jar PET preform mold manufacturers offer a wide range of customization options to meet the specific needs and preferences of their clients. Whether producing molds for standard jar sizes or creating custom molds for unique shapes and designs, these manufacturers work closely with their clients to develop molds that align with their product requirements, branding objectives, and production processes. Additionally, jar PET preform mold manufacturers can incorporate features such as multi-cavity configurations, interchangeable inserts, and hot runner systems to enhance productivity, flexibility, and efficiency in mold production and usage.

In addition to their precision and customization capabilities, jar PET preform mold manufacturers prioritize quality and reliability in every aspect of their operations. From the selection of raw materials to the manufacturing process to the final inspection and testing of finished molds, these manufacturers adhere to strict quality control standards to ensure that each mold meets or exceeds industry specifications and customer expectations. This commitment to quality assurance is essential for delivering molds that produce consistent, high-quality preform blanks for jars, thereby enhancing the reputation and competitiveness of their clients in the marketplace.

Furthermore, jar PET preform mold manufacturers play a crucial role in driving sustainability and environmental responsibility in the packaging industry. By optimizing mold designs for material efficiency, minimizing waste in the manufacturing process, and promoting the use of recycled and recyclable materials, these manufacturers help their clients reduce their environmental footprint and minimize packaging waste. Additionally, jar PET preform mold manufacturers can provide guidance and support to their clients in implementing sustainable packaging practices, such as lightweighting, material substitution, and end-of-life recycling solutions, to further enhance their sustainability efforts and meet consumer demand for eco-friendly products.

Another important aspect of jar PET preform mold manufacturers' contributions to the packaging industry is their commitment to innovation and continuous improvement. Through ongoing research and development initiatives, these manufacturers are constantly exploring new materials, technologies, and manufacturing techniques to enhance mold performance, efficiency, and longevity. By staying at the forefront of technological advancements and industry trends, jar PET preform mold manufacturers enable their clients to anticipate and respond to the evolving needs and challenges of the marketplace, ensuring that they remain competitive and successful in a rapidly changing landscape.

In conclusion, jar PET preform mold manufacturers are indispensable partners in the packaging industry, driving excellence, efficiency, and innovation in the production of packaging solutions. With their precision engineering, customization capabilities, and commitment to quality and sustainability, these manufacturers enable companies to create high-quality, efficient, and environmentally responsible packaging solutions that meet the needs and expectations of consumers and businesses alike.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français