Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

The plastic manufacturing industry is in the midst of a significant transformation, largely driven by advancements in blow moulding technology. Among the critical components in this process are the blow moulds themselves, which play a pivotal role in determining the quality, efficiency, and sustainability of the final products. As manufacturers seek to enhance production capabilities and reduce environmental impact, innovations in blow moulding molds are reshaping the landscape of plastic production.

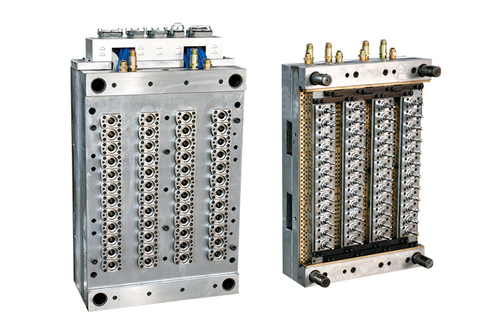

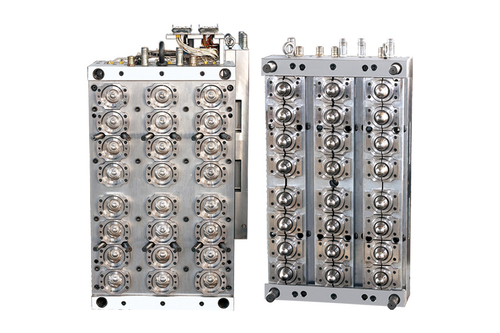

Blow moulding is a manufacturing process used to produce hollow plastic parts, such as bottles, containers, and automotive components. The process involves heating plastic until it is malleable and then inflating it within a mold to achieve the desired shape. The design and quality of the blow mould significantly affect production efficiency, material usage, and the final product's performance.

As consumer demand for lightweight, durable, and environmentally friendly plastic products grows, manufacturers are increasingly focusing on optimizing blow mould design and production techniques. This shift is crucial not only for meeting market needs but also for complying with stringent environmental regulations.

Recent advancements in computer-aided design (CAD) and 3D printing technologies have revolutionized the way blow moulds are created. Manufacturers can now design complex mould geometries that enhance air flow and cooling, to improved cycle times and higher-quality products. 3D printing, in particular, allows for rapid prototyping of mould designs, enabling companies to test and refine their products more efficiently than ever before.

Moreover, innovations in materials used for manufacturing blow moulds have led to more durable and lightweight options. Traditional metal moulds are now being complemented by advanced polymers and composite materials that offer thermal stability and corrosion resistance. These developments not only improve the lifespan of the moulds but also reduce production costs and energy consumption.

Sustainability is a pressing concern for manufacturers across all sectors, and blow moulding is no exception. As the industry moves towards more eco-friendly practices, the design and production of blow moulds are being re-evaluated to minimize waste and environmental impact.

One notable trend is the adoption of closed-loop systems, where the scrap generated during the blow moulding process is reused to produce new products. By integrating this approach, manufacturers can significantly reduce material waste and lower their overall carbon footprint. Innovations in mould design that facilitate easier recycling and reprocessing of materials are becoming increasingly important in achieving these sustainability goals.

Additionally, the use of biodegradable and recyclable materials for producing blow-moulded products is gaining traction. Manufacturers are exploring bio-based polymers that can serve as alternatives to traditional plastics, aligning with consumer preferences for sustainable options.

The rise of customization in consumer products has prompted a shift in how blow moulds are designed and manufactured. Today's consumers expect personalized solutions, and manufacturers are responding by creating molds that enable a higher degree of customization without significantly increasing production costs.

Advanced blow mould designs allow for variations in wall thickness, texture, and shapes, providing manufacturers with the flexibility to produce unique products tailored to specific customer needs. This capability is particularly valuable in industries such as cosmetics, food and beverage, and automotive, where branding and differentiation are key to success.

Precision engineering in blow mould design is also critical for ensuring product consistency and quality. By utilizing advanced simulation software, manufacturers can predict how the mould will perform during the production process, enabling them to make adjustments before production begins. This proactive approach helps to minimize defects and optimize manufacturing efficiency.

Despite the promising advancements, the blow moulding industry faces several challenges. The initial investment in high-quality blow moulds can be significant, making it essential for manufacturers to strike a balance between cost and quality. Additionally, fluctuations in raw material prices can impact production costs, necessitating strategic sourcing and supplier partnerships.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français