Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

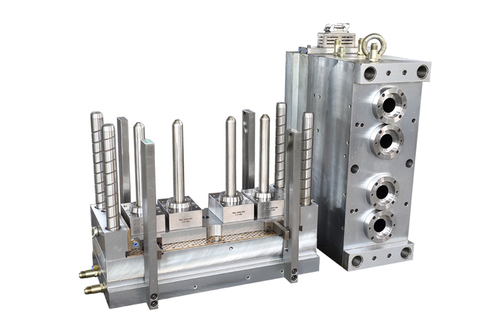

It is a heat exchanger. In order to ensure the molding quality and production efficiency, it is necessary to use the medium to heat or cool the mold and control the temperature within a reasonable range. The productivity of the mold depends on the speed of the heat exchange of the mold. The speed of mold heat exchange depends on mold heat exchange. Mold heat exchange depends on melt temperature, demold temperature and plastic.

The temperature control system for high-precision, mass-production molds is carefully designed. Sometimes, a special temperature regulator must be designed to strictly control the temperature of each part of the mold. The control system of injection mold temperature is one of the difficult points of mold design. For these molds, if the surface heat dissipation is fast, the heat of the melt alone is not enough to maintain the mold temperature, so the mold needs to be equipped with a heating system to heat the mold before or during the injection to ensure that the mold runs well.

Some molds have both a cooling system and a heating system. One situation is that in cold regions or large molds, the mold must be preheated before production. When the mold temperature reaches the molding process requirements, the heating system can be turned off. If the mold temperature is higher than the temperature required for the plastic molding process, turn on the mold cooling system to keep the mold temperature at the desired temperature.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français