Established in 1992 with a registered capital of $5.2 million USD from Australian sole-ownership enterprises, and boasts a 72,000 square meter factory zone. - Custom Injection Molding Machine Manufacturers

In recent years, the food and beverage industry has seen significant shifts in packaging technologies, with blow molds the charge as one of the impactful innovations. Blow molding, a manufacturing process used to create hollow plastic parts, has become a cornerstone of modern packaging solutions, particularly for bottles and containers used in the food and beverage sector. As consumers demand more sustainable, efficient, and customizable packaging, blow molds are increasingly shaping the future of packaging in this industry.

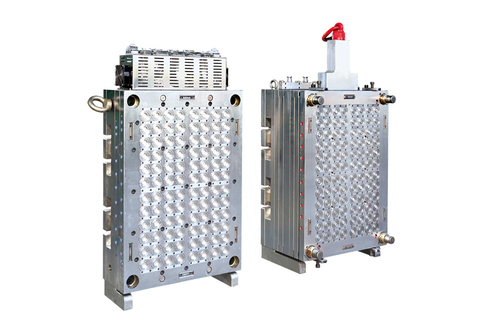

Understanding the Blow Molding Process

Blow molding is a technique where plastic is heated and formed into a preform, which is then inflated into a mold cavity to create the desired shape. In the food and beverage industry, blow molds are primarily used to produce plastic bottles and containers, from simple water bottles to more intricate, uniquely shaped containers for specialty products. The process allows manufacturers to create high-quality, lightweight containers with intricate designs and custom shapes, offering versatility and flexibility in packaging.

Blow molds are commonly used to produce containers made from materials like polyethylene terephthalate (PET), which is widely used in beverage packaging due to its strength, clarity, and recyclability. The use of blow molds has revolutionized the way food and beverage products are packaged, offering advantages in production speed, cost-efficiency, and customization that have transformed the industry.

Driving Sustainability in Packaging

One of the key benefits of blow molds in the food and beverage industry is their contribution to sustainability efforts. As consumers become more environmentally conscious, there is increasing pressure on manufacturers to reduce plastic waste and adopt more sustainable practices. Blow molding is an essential part of this transformation, as it enables the production of lightweight, durable containers that require less material to produce compared to traditional packaging options.

Moreover, blow molds allow for the efficient use of recyclable materials such as PET, which is one of the recycled plastics worldwide. With blow molding, manufacturers can create containers that are not only easier to recycle but also require less energy and resources to produce. This helps reduce the environmental impact of packaging, aligning with the growing demand for eco-friendly solutions in the food and beverage industry.

Speed and Efficiency in Production

In an industry where speed and efficiency are paramount, blow molds have proven to be a game-changer. The process allows for high-volume production with relatively low costs, which is essential for the food and beverage sector, where products must be packaged quickly and consistently. Blow molding machines are capable of producing large quantities of containers in a short amount of time, ensuring that manufacturers can keep up with the high demand for bottled products.

Additionally, the flexibility of blow molds enables manufacturers to create packaging that meets the specific needs of their products, whether it’s a bottle with a unique shape for brand differentiation or a specialized container designed for product preservation. This adaptability is crucial for food and beverage companies that need to respond to market trends and consumer preferences quickly.

Customization and Brand Differentiation

In an increasingly competitive market, food and beverage companies are looking for ways to stand out on store shelves and build stronger brand identities. Blow molds provide an effective solution for customization, offering the ability to produce bottles and containers in a variety of shapes, sizes, and colors. Manufacturers can create packaging that aligns with their brand’s aesthetic and appeals to consumers' visual preferences.

Blow molds also allow for the incorporation of unique design features, such as textured surfaces, embossed logos, or ergonomic shapes that enhance both functionality and visual appeal. This level of customization is vital for companies looking to distinguish themselves from competitors and create packaging that resonates with their target audience. By utilizing blow molds, food and beverage manufacturers can offer products that not only look appealing but also provide enhanced usability and convenience.

Improving Product Safety and Quality

Blow molds also play a crucial role in improving the safety and quality of food and beverage products. Packaging is a critical aspect of preserving the freshness, integrity, and safety of consumables, and blow-molded containers are designed to protect products from contamination, spoilage, and external factors like moisture or light.

English

English 中文简体

中文简体 русский

русский Español

Español Français

Français